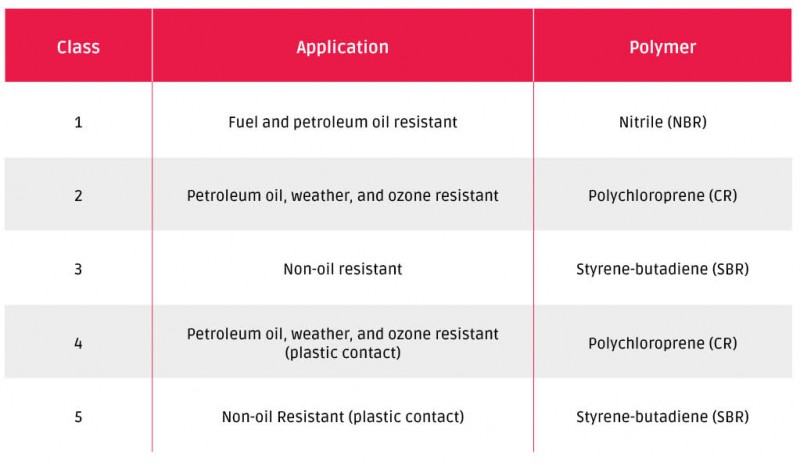

A widely recognized standard in military applications is MIL-PRF-6855. This specification meticulously outlines a range of synthetic rubber polymers, each tailored to meet specific operational requirements. Within this framework, various classes are distinguished, highlighting the unique properties and performance characteristics of different polymers. Each class serves as a crucial guide, ensuring that the appropriate materials are chosen for demanding military environments.

Class:

Type (Class 2 and 4 only) – Resistance to Ozone

Type A – High Ozone Concentration (100 pphm)

Type B – Low Ozone Concentration (50 pphm)

Grade – ASTM D2240 Type A Durometer Hardness Value

30–80

A typical call out would then be MIL-PRF-6855 Rev F Class 1 Grade 60. This would be a 60 Shore A Nitrile Rubber good with good fuel and oil resistance.

*Note

*MIL-R-6855 was a material specification replaced by AMS-R-6855. Then in 2010, MIL-PRF-6855 became the current standard. MIL-PRF is identified as a performance specification. AMS-R-6855 and MIL-PRF-6855 feature testing under the same physical properties.

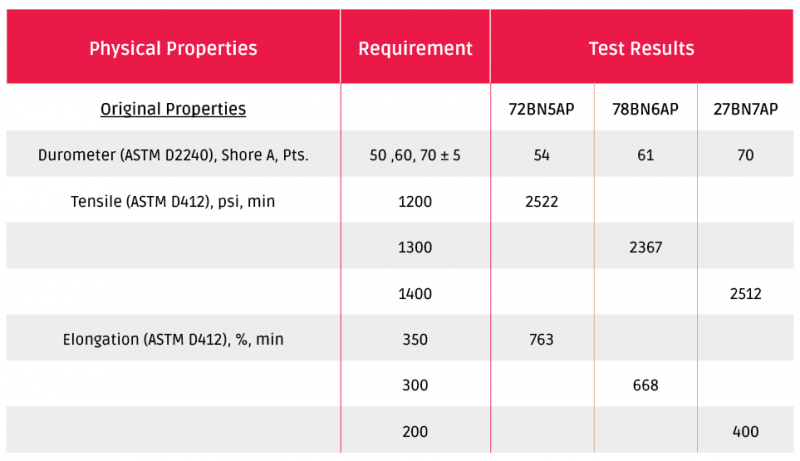

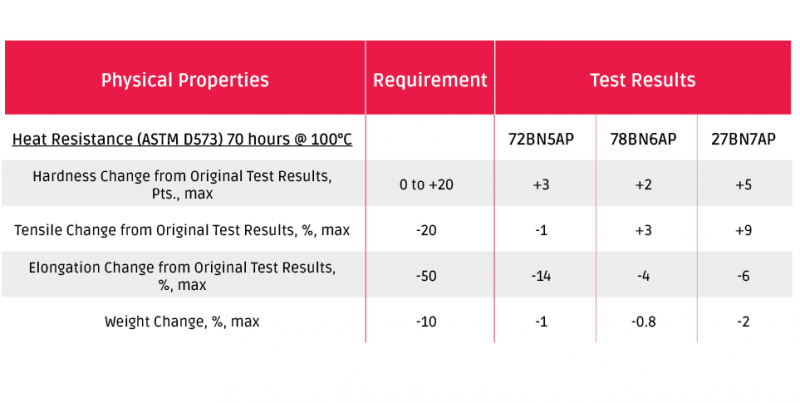

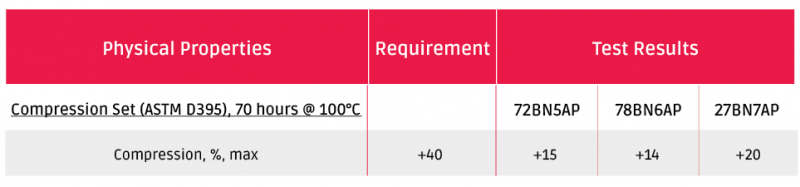

Apple Rubber specializes in providing various rubber products for sealing applications, with a particular focus on the Class 1 specification. Our formulation includes several different types of acrylonitrile-butadiene rubber (NBR). We have developed and tested three compounds specifically for this specification. Each of these compounds is designed to be processed in our rubber injection division.

These compounds not only meet the physical property requirements outlined in the MIL-PRF-6855 specification but are also tailored for optimal processing performance in rubber injection machines. Key features of these compounds include excellent mold release, superior flow through runners and cavities, and minimal mold deposits over time.

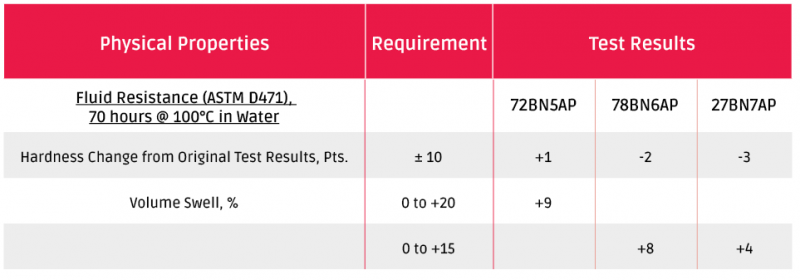

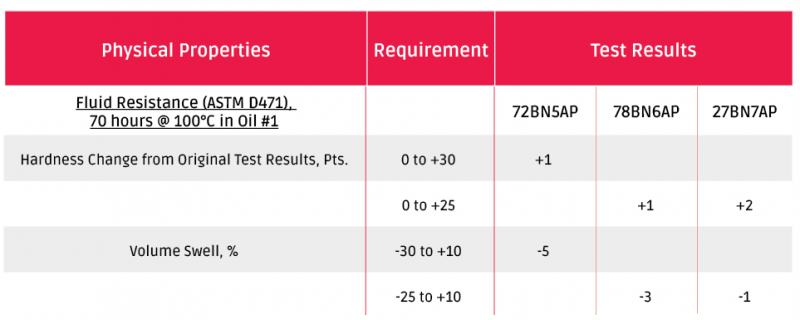

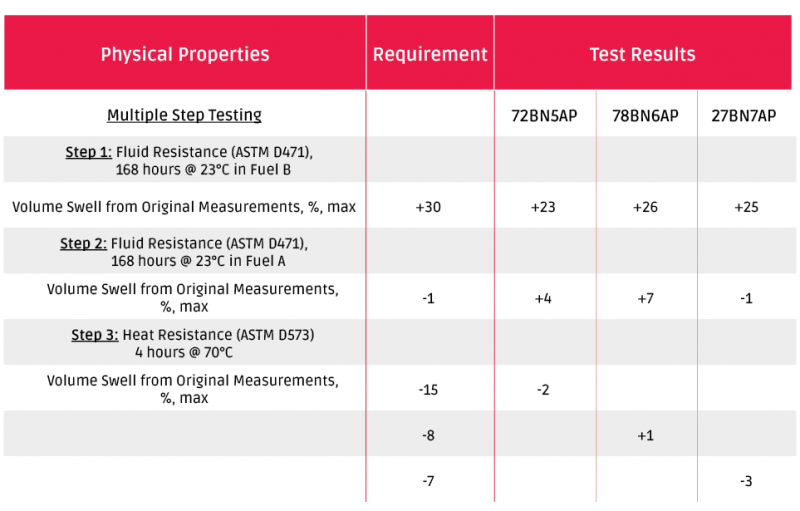

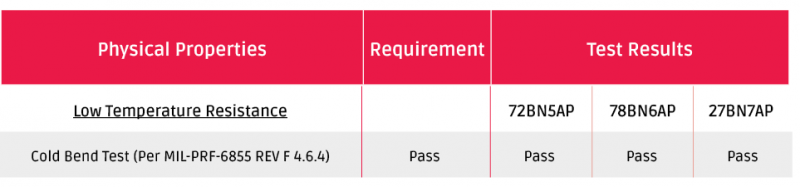

Below is the testing for three compounds.

Summary

Key aspects of this specification include testing in all types of fluids: water, oil, and fuel. Oil #1 is classified as a moderate swell oil. The fuels tested are Fuel A (normal gasoline), Fuel B (high-octane gasoline), and a dry-out test. Dry-out tests are useful for determining whether a seal will shrink once it is removed from the fluid, which could lead to leaking upon reuse. This specification employs a flat bend low-temperature test, as opposed to the standard ASTM D2137 impact test.

If you are looking for other rubber compounds to meet different military specifications,, feel free to contact us.