Investigating Fowl Play

Chickens on several farms were not drinking enough water due to a malfunctioning seal in their feeders. These underweight and underdeveloped chickens were creating a costly situation for both the chicken farmers and the equipment manufacturer who had guaranteed the feeders and already sold millions around the world.

A Rotten Egg

The Apple Rubber team went to the manufacturer's facility to investigate and found two potential sealing problems. First, an o-ring configured around a small rod that would often stick, preventing any water from getting through. Second, the potential for the seal to be completely blown off the rod by the high pressure of the system, allowing too much water to spray through.

Microminiature applications like these are one of Apple Rubber's specialties, so our team was quick to develop a plan.

Ruffling Feathers

First, we had to consider environmental factors. Water content differed dramatically between farms. At some, water heavy in mineral content was being used; at others, the water was highly chlorinated. Second, the feeders were regularly cleaned with high pressure water and solvents, so the seal we selected would have to withstand this process. Third, nutrients and medicines were often administered through these water systems as well.

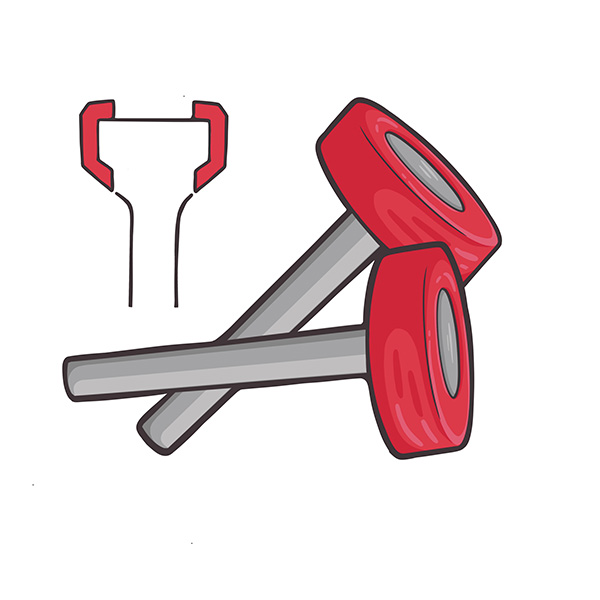

In order to work with all these factors, the Apple Rubber team provided two possible solutions. For our first, we designed a microminiature seal made of fluorocarbon which would withstand the environmental factors and act as a seal and force limiter.

However, we knew that seals generally aren't effective force limiters. That's why we also offered a rubber-bonded-to-metal seal in which the metal would act as the force limiter and the seal only as a seal. The metal bond added the necessary stability to the seal, eliminating potential swelling and disfiguring a cost-effective solution in more ways than one.

Outcome

Our client chose the second solution. Although it required some changes to the feeder, the seal combined two parts into one, completely eliminating the assembly process and reducing assembly costs. Therefore, our client could purchase a better seal for the same amount of money.