Rubber bloom refers to a white, milky dust or film that can appear on the surface of rubber. It occurs when additives within the rubber compound migrate to the surface. These additives—like accelerators, curing agents, or lubricants—are typically dissolved within the rubber but can recrystallize, leading to the formation of this surface bloom.

To protect the rubber from ozone or UV exposure, paraffin wax is often added to rubber compounds, causing the bloom to form on the surface. This phenomenon can frequently be observed on new rubber tires. Additionally, eurcamide may be included to reduce the friction of the rubber surface.

In our previous discussion, “Rubber Blooms: What Are They and Why Are They Important,” we highlighted two processes for removing blooms: wiping the rubber with alcohol or post-curing the rubber to eliminate the bloom by burning it off.

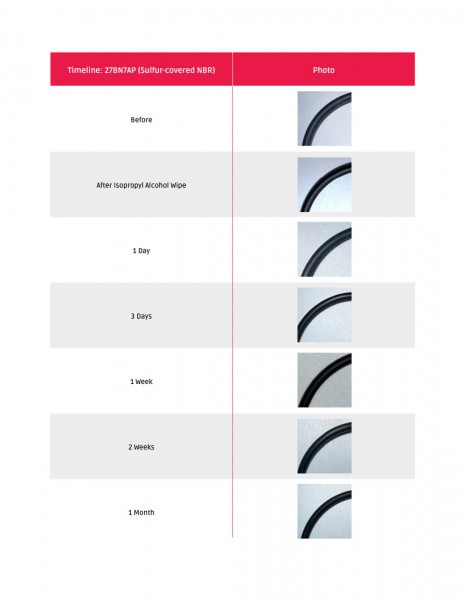

**Isopropyl Alcohol Wipe**: Using isopropyl alcohol is a suitable option for removing residues, as it does not deteriorate most rubber compounds due to the quick exposure of the alcohol on the rubber surface.

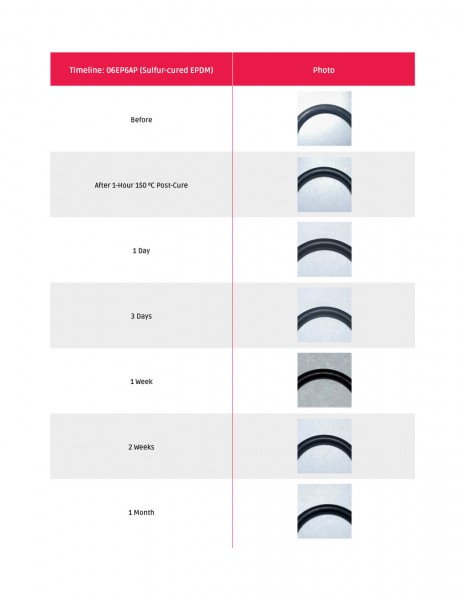

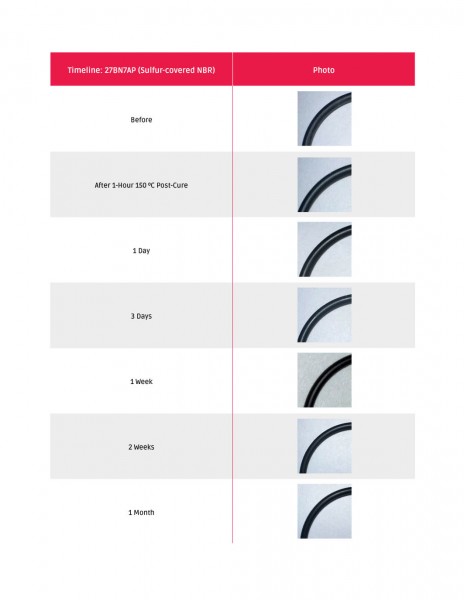

**1-Hour Post-Curing at 150 °C**: Post-curing is performed to eliminate surface bloom. During this process, the parts are placed in a circulating oven for a specified duration and temperature based on the curing system used.

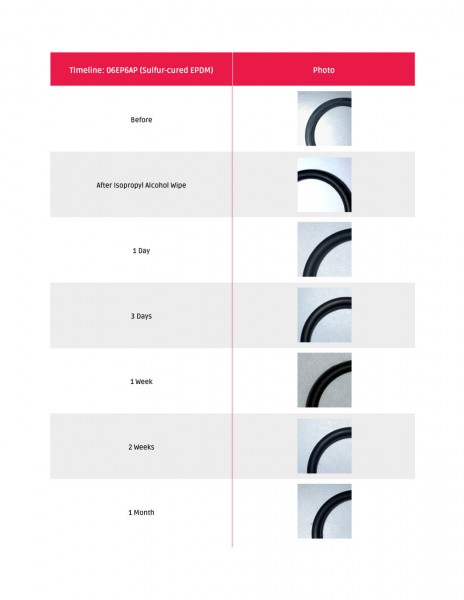

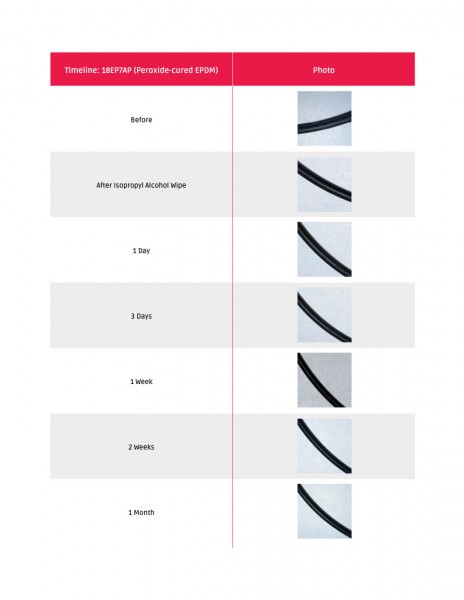

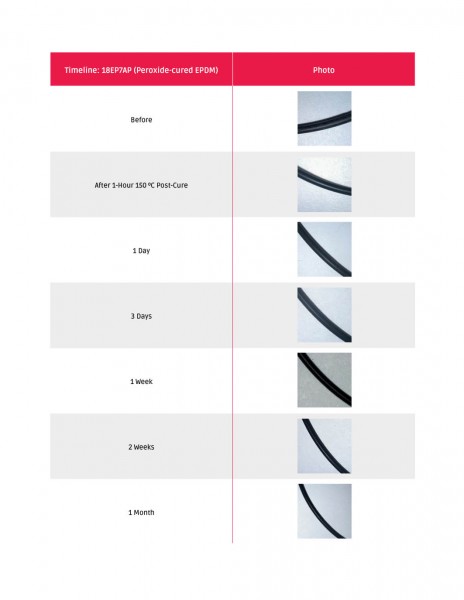

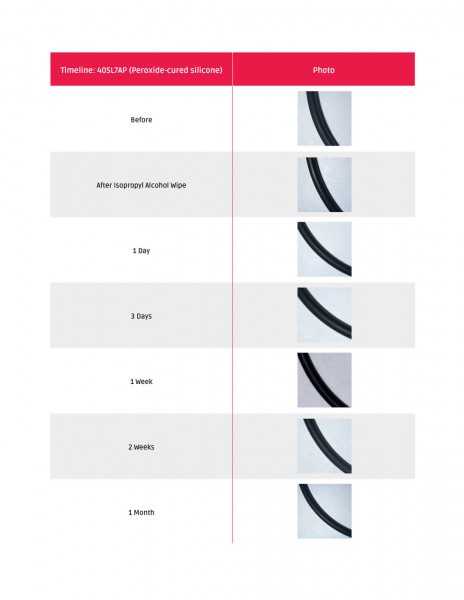

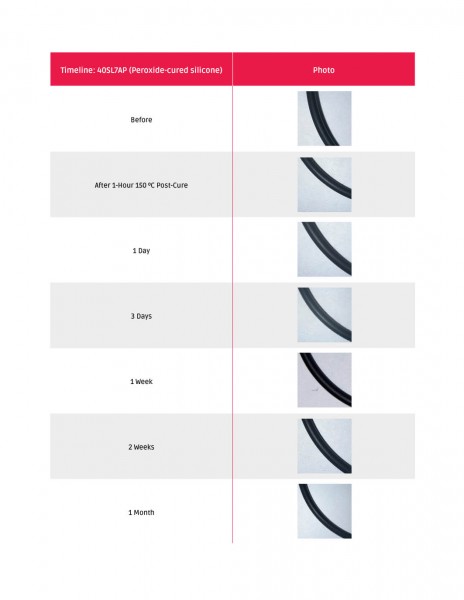

In most cases, the bloom will be removed, but it may return over time. So, when can we expect the bloom to reappear? Four compounds were examined using the isopropyl alcohol wipe and post-curing methods before the removal, immediately after, and then at intervals of 1 day, 3 days, 1 week, 2 weeks, and 1 month after the bloom removal.

06EP6AP: Sulfur-cured EPDM. Depending on the sulfur system, these can bloom unused sulfur to the surface.

27BN7AP: Sulfur-cured NBR. Waxes are added to NBR to help prevent cracking to ozone or UV during storage.

18EP7AP: Peroxide-cured EPDM. Unconsumed peroxide can bloom to the surface.

40SL7AP: Peroxide-cured silicone. High consistency peroxide cure can bloom peroxide over time. Liquid silicone rubber is platinum cured, which will not bloom.

Below are tables with images corresponding to each selected timeline. For each compound, there was noticeable bloom on the o-ring before removal. After applying each removal technique, the bloom was no longer present, and this trend continued throughout the testing period.

Although bloom is often perceived as a defect in rubber, it is usually an intentional characteristic that does not impact the rubber’s performance in its intended application. If necessary, formulation adjustments can be made to minimize bloom.

However, it’s important to note that bloom can sometimes be beneficial, so removing it might not be advisable. We have seen applications where bloom is removed, and the friction forces are too great for the devices. Other types of lubricants then needed to be added, or the compression forces in the design had to be reduced.

For more information, please don’t hesitate to contact our engineers today.

Click on a table to enlarge it.