Customers often ask whether or not cleaning o-rings can have a negative impact on the materials they’re made from. There are many different ways to clean o-rings, but just three that we frequently use at Apple Rubber, each of which are intended to preserve an o-ring’s physical and chemical properties. To confirm this, we tested o-rings made from 32BN7AP, 20EP7AP, 27VT7AP, and 06SL7AP using different cleaning solutions and processes to determine what effects (if any) they had on the o-rings’ post-cleaning performance.

Why are we testing?

Performance testing is essential and valuable to understanding a material’s response to environmental alterations and stressors. The results of this testing allows us to characterize the uses and limits of an elastomer product. Adjustments to a polymer’s structure, molecular weight, compounding ingredients, cure system, time, and temperature directly affect elastomer properties and their response to environmental exposure. Although performance testing methods will not act in exact correlation to active performance, the results will ensure that all materials are within industry-quality requirements and be in excellent condition for our customers.

Properties that were evaluated include:

- Tensile Strength = the maximum resistance a material has to breaking under tension.

- Ultimate Elongation = the point of elongation at which a rupture/break occurs.

- Hardness = the relative resistance of the surface of a rubber sample to indentation (measured using a durometer).

- Volume Swelling = a general indicator of how resistant a material is to a given fluid.

Uncleaned -214 o-rings were used as a control group to compare against the properties of the -214 o-rings that were put through a cleaning process. These groups are differentiated by “dirty” and “clean” in the following sections.

Test Components

Materials

(All test materials are FDA Food Grade Compounds)

32BN7AP – 70 Shore A NBR

20EP7AP – 70 Shore A EPDM

27VT7AP – 75 Shore A FKM

06SL7AP – 70 Shore A Silicone

Cleaning Methods

-214 o-rings were cleaned using the following:

- Method 1: Wiping with 100% Isopropyl Alcohol for 30 to 60 seconds

- Method 2: Washing in an Ultra Sonic Machine for 15 minutes using a 50/50 mix of Isopropyl Alcohol/Water

- Method 3: Sending through the washer in our clean room with a 1% Valtech Solution

Testing

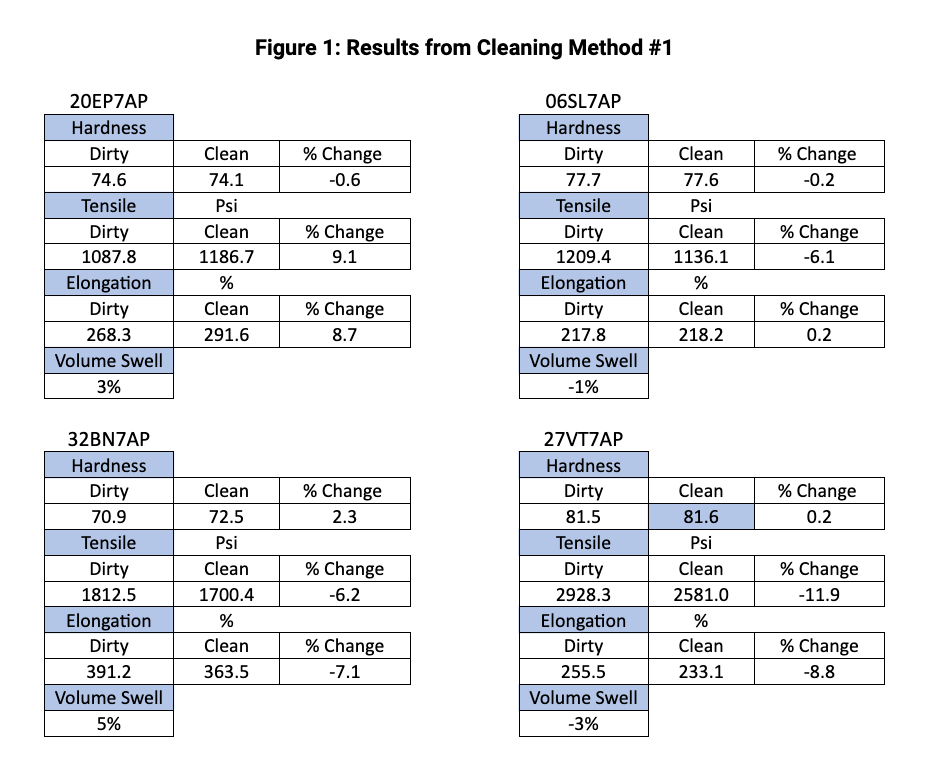

Method 1: Wiping for 30 to 60 seconds with 100% Isopropyl Alcohol

Using 2-Ply Low Lint wipes saturated with 100% Isopropyl Alcohol, three -214 o-rings (0.984 I.D. and 0.139 Cross Section respectively) of each kind were wiped down for 45 seconds. Following the cleaning, the ring properties were tested. The results were as follows:

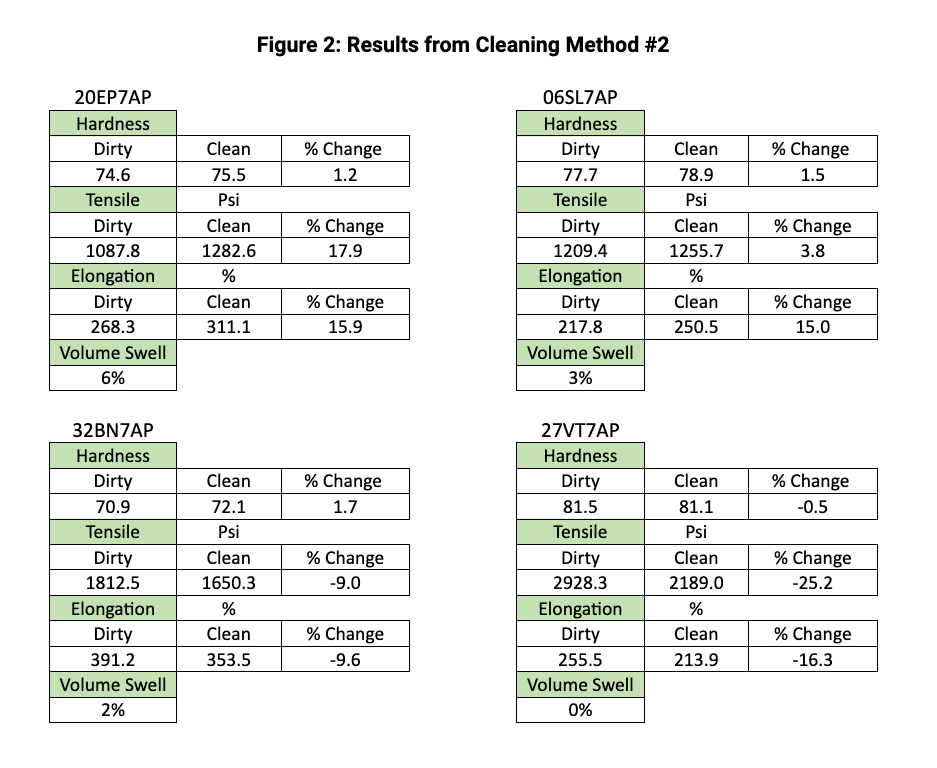

Method 2: 50/50 mix of Isopropyl Alcohol/Water in an Ultra Sonic Machine for 15 minutes

Ultrasonic cleaning works by transmitting high-frequency sound waves through liquid to clean the surface of anything immersed in the liquid. With a 50/50 solution of Isopropyl Alcohol and water, three of each -214 O-rings (0.984 I.D. and 0.139 Cross Section respectively) were immersed and cleaned for 15 minutes. Following the cleaning, the rings were tested and the results were as follows:

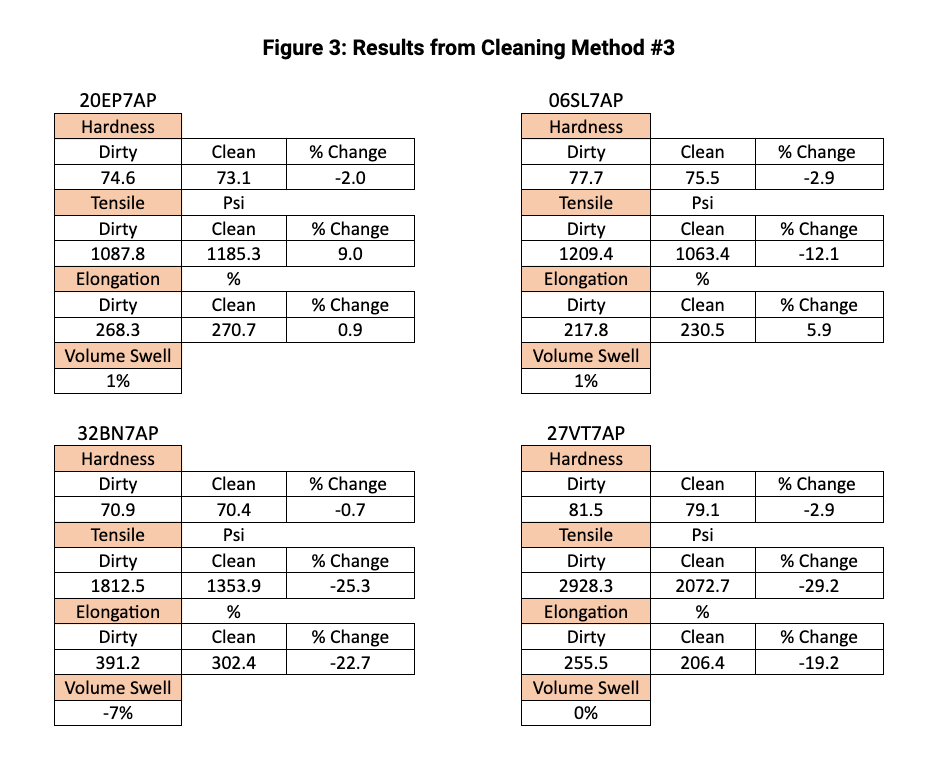

Method 3: Automatic Ultrasonic washer, 1% Valtech solution

In our in-house clean room, Apple Rubber engineers are able to mold, post cure, and clean o-rings all in one spot. The -214 (0.984 I.D. and 0.139 Cross Section) o-rings went through our clean room’s washer with a 1% Valtech solution. The automated process went through one wash cycle, two rinse cycles, and one dry cycle. Following the cleaning, the rings were tested. The results were as follows:

So, does cleaning damage our products?

Based on the findings from the tests of our three favored cleaning methods, we concluded that the performance of the cleaned o-rings performance were minimally altered and remained within range for industry-quality requirements across all methods. As such, we have determined that cleaning Apple Rubber o-rings does not impact the products negatively.

Ready to learn more?

Get in touch with us here!