For many medical devices and electronic components, it is critical to have precise manufacturing, cleaning, and testing of parts involved. One way that Apple Rubber meets these requirements is by having an ISO 14644-1:2015 (E) Class 7 cleanroom (applerubber.com/quality/certified-cleanroom). Specifically, our cleanroom is equipped with a Sprayflood washer that is capable of high impingement force cleaning of rubber parts. This precision washing system uses the most highly purified water available. All water entering the washer is purified using an advanced double-pass reverse osmosis water treatment system. Both the water treatment and washing systems have been tested to run at optimal wash cycle parameters. The purified water system, as well as the wash cycle parameters, have been tested to verify that all appropriate requirements are met and are evaluated to make necessary improvements when possible.

The cleaning process of the Sprayflood washer consists of a wash stage, two rinse stages, and a drying stage. The wash stage uses a mixture of 3% detergent and 97% purified water, where the water is circulated through a 1‐micron filter to remove particulates. Next, the rinse consists of two stages: a fresh water rinse and a spray rinse. The first rinse uses fresh purified water, and the second rinse sprays recirculated purified water. During the rinse stage, water is filtered through a 10‐micron filter to remove particulates, and after the rinse stage, the rinse water is circulated from the tank through a series of filters, including: a 185nm UV total organic carbon (TOC) purifier, a mixed bed DI, a 0.35‐micron filter cartridge, and a 254nm UV for inactivation, before returning to the tank. The last stage dries the part using heated air and a vacuum, with air passing through a 0.3‐micron HEPA filter before being heated and passed over the parts.

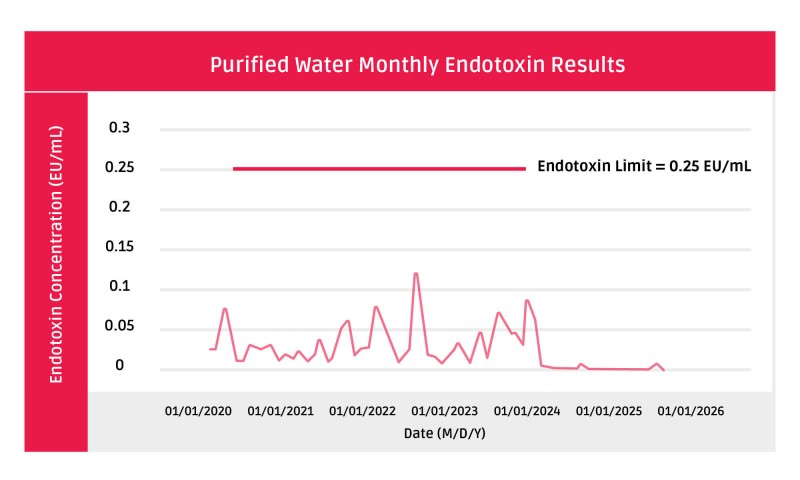

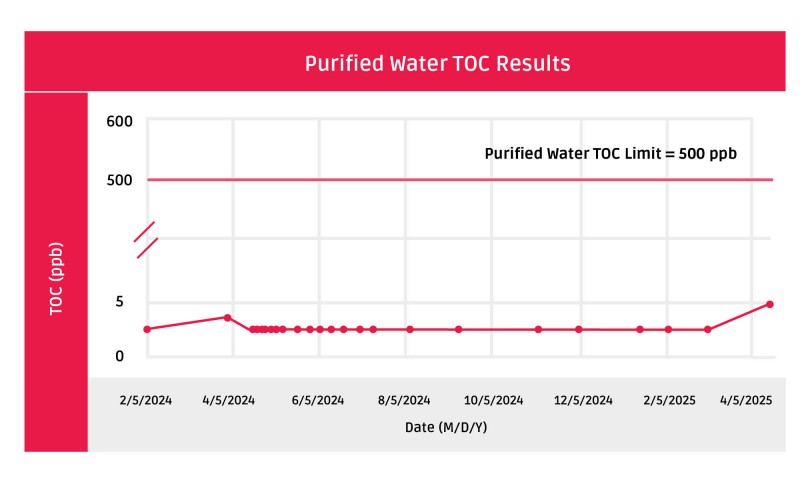

To limit the risk of contaminating rubber parts with pyrogens in this process, we measure the level of endotoxin contamination in the water purification system. This was chosen as a sampling point because it is the last place in the manufacturing process that water comes into contact with the rubber parts, therefore it is the last point of endotoxin contamination. Endotoxins in the cleanroom’s purified water are measured, documented, and reviewed monthly with a specification limit of 0.25 EU/mL to align with USP Water for Injection specifications, as shown below in Figure 1. Additionally, the cleanroom’s purified water TOC is measured in the purified water loop with a TOC specification maximum of 500 ppb to align with USP WFI specifications, as shown below in Figure 2.

Figure 1. Purified Water Monthly Endotoxin Results. Monthly endotoxin concentrations of the purified water system for the last five years.

Figure 2. Purified Water TOC Results. Total organic carbon count of the purified water loop for the last year.

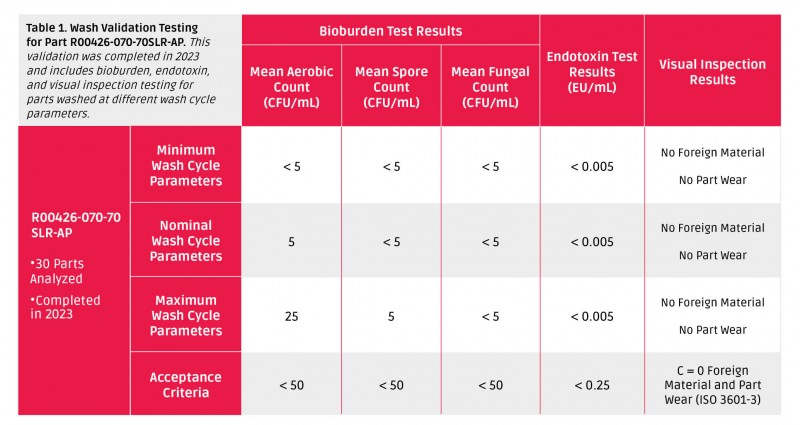

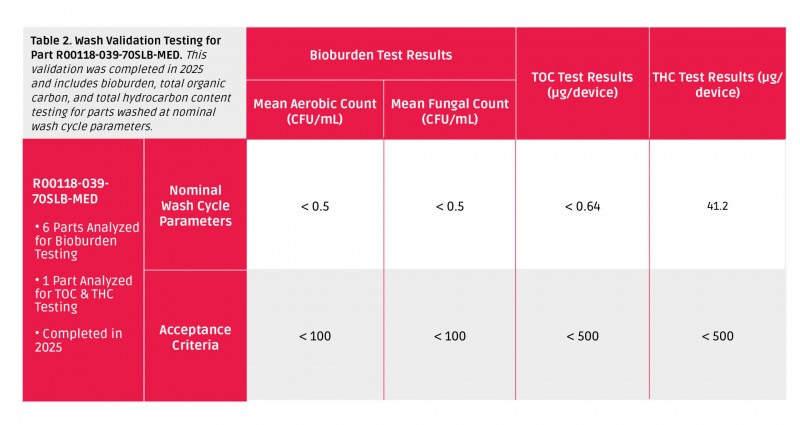

Cleanroom Washed Parts – Validation Testing

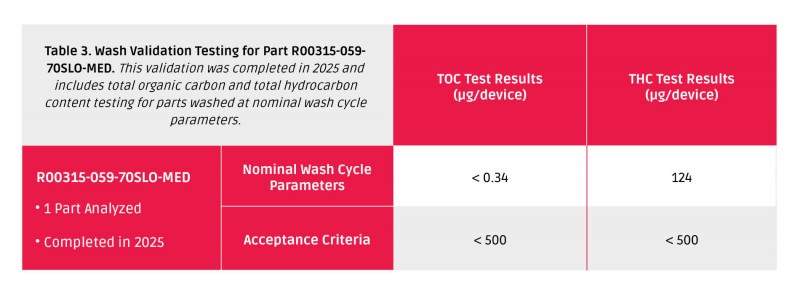

In addition to regularly testing the purified water, parts have also been tested to confirm wash requirements in a wash or cleaning validation. The main purpose of a wash validation is to provide evidence that our washing process and cleanroom methods meet the preferred cleanliness levels and acceptance criteria for the varied washing cycles. The parameters that were tested during the performed wash validations include the washer’s interval flood wash, drain, fresh rinse, spray rinse, hot blow, vacuum dry, washing agent concentration, media age, and basket fill, as mentioned previously. These parameters were varied to denote a “minimum,” “nominal,” and “maximum” wash cycle, as seen in the tables below.

As shown in the tables, it was concluded that these varied wash cycles produced parts that still met the acceptance criteria for all testing performed. Through bioburden testing, endotoxin testing, visual inspection, total organic carbon testing, and total hydrocarbon content testing, we validated that our cleanroom washing system and Sprayflood washer efficiently cleans parts and meets all customer-required criteria.