As the world navigates new developments in Artificial Intelligence (AI), I wanted to explore how different AI systems address some common questions we’ve encountered at Apple Rubber over the years. This review examines the responses from three AI platforms: Google Gemini, ChatGPT, and Grok 3. Please note that I am not an expert in the field of AI.

My basic understanding is that these AI platforms are advanced algorithms that pull real-time information from publicly available sources to provide users with answers or information. Below are the questions we posed to three AI platforms, along with their responses.

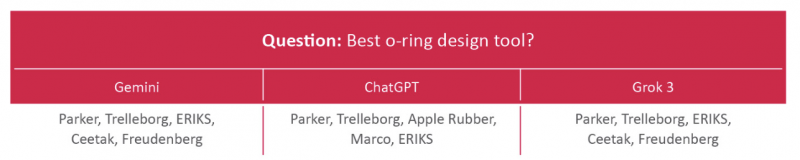

Of course, we are biased on this question and should always be (we’re Apple Rubber, after all). But it does make sense to see these AI systems provide these results, since typically larger companies tend to receive higher traffic to their websites. However, this does not always indicate the best tool.

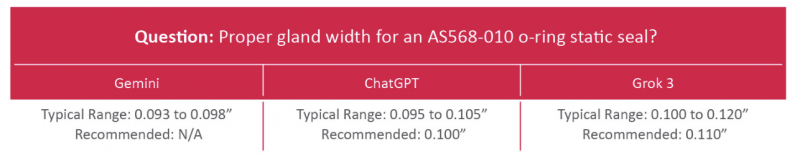

All three AI platforms provided valuable information for key considerations and suggested design configurations. Note: Using our Apple Rubber calculator would yield a nominal value of 0.105 inches.

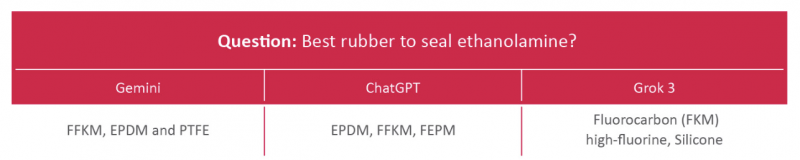

I believe that material compatibility questions can be challenging due to the inherent trade-offs involved. Amines are particularly difficult to seal because most rubber materials are not compatible with them. Additionally, some amines can act as solvents, which may extract plasticizers from the rubber and potentially contaminate the system.

In my opinion, ChatGPT provided a better recommendation. Standard FKM tends to harden in amine environments, while higher fluorine content performs somewhat better. Although polymers like ETP and FFKM can be effective, they each are more expensive.

One of my recommendations would be a low-oil, peroxide-cured EPDM (Ethylene Propylene Diene Monomer), which should also perform well in these applications. I would also recommend AFLAS, though less frequently mentioned online, can be an excellent choice due to its compatibility and lack of plasticizers that could be extracted.

Summary

I believe all these AI programs provide valuable background information in their responses. A design engineer should read as much as possible to ensure they develop the correct design. I anticipate a strong push within the rubber industry to publish information, which will help ensure that suppliers’ products are included in these design tools. This effort will only improve these systems further.

If you are looking for a human touch on rubber design, feel free to contact us.