Silicone is a type of synthetic rubber used in various industries, from medical devices to aerospace engineering. Its synthetic nature makes it more suitable for certain fields compared to natural rubber. Understanding silicone rubber is important for choosing the right material for your specific needs.

Quality as a Sealing Material

When a seal is needed in high-heat environments, silicone rubber’s resistance to elevated temperatures is a key advantage. It maintains consistency and shape under these conditions, making it ideal for food processing and medical equipment. Silicone performs well in cold environments, with a temperature range from -100°F to +500°F (-60°C to 230°C). In areas with temperature fluctuations, like electronics, silicone is a logical choice for sealing.

Silicone rubber is highly resistant to weathering and harsh outdoor conditions. This includes water, chemicals, acids, oil, and fungi. The durability against these elements ensures long-lasting, effective performance in applications like construction or weatherproofing.

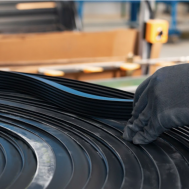

Flexibility and Moldability

Despite being tasteless, non-toxic, biocompatible, and odorless, silicone rubber is excellent for making custom molded shapes thanks to its flexible nature. It can also be formulated into a variety of hardness levels, enhancing its durability. Additionally, silicone rubber’s versatility allows for vibrant colors to be implemented because of its pigmentation, since these colors can be easily mixed into the silicone base.

These qualities support a wide range of applications for silicone rubber. It can be found in consumer products such as fitness watches and kitchenware (like baking molds and storage containers). In the medical field, it’s used for implants, catheters, and medical pumps. Silicone rubber also helps keep electronics like phones and smartwatches waterproof.

Strong Safety Standards

One key advantage of silicone rubber is safety. It meets strict industry standards required for its various applications. In the food and beverage industry, silicone rubber complies with regulations set by groups like the Food and Drug Administration, thanks to its non-toxic, tasteless nature. It is also resistant to bacteria and easy to clean.

In healthcare, silicone rubber is considered a medical-grade material because it can be easily sterilized without losing its effectiveness. This allows it to be used safely in procedures involving the human body, such as implants. For everyday consumer products, silicone rubber is free of harmful chemicals that could affect health, such as bisphenol A (BPA).

Reach Out

We offer high-quality molding capabilities for parts and seals. Get in contact with us today for your silicone rubber needs.