At Apple Rubber, located in the Buffalo, New York area, we understand the effects of cold weather on materials. It’s an ideal time to discuss some of the compounds we offer that are suitable for cold-temperature applications.

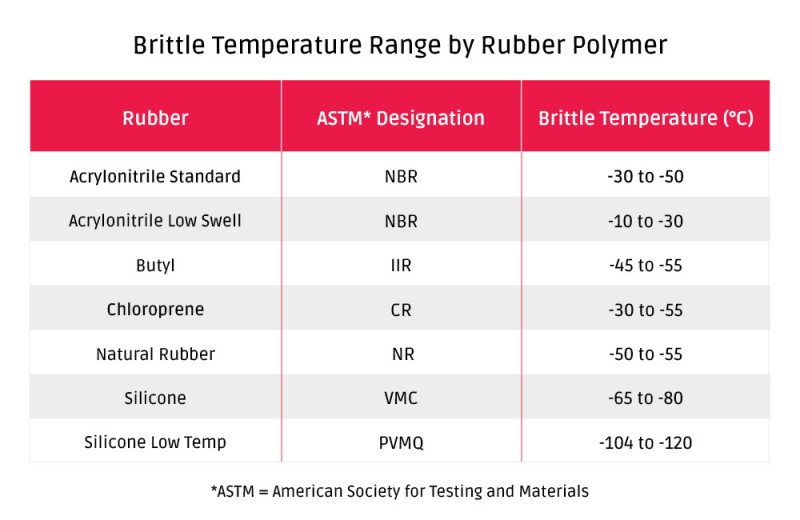

When rubber is exposed to low temperatures, its elastic properties can change significantly. The extent of these changes depends on both the type of polymer and the temperature itself. Typically, you may notice a decrease in flexibility, an increase in compression set and brittleness, and a loss of sealability. Fortunately, these properties usually return to normal once the rubber warms up again.

A good indicator of rubber performance is the glass transition temperature (Tg). This is the temperature at which rubber transitions into a glassy or leather-like state. The standard method for testing Tg is differential scanning calorimetry (DSC). Another test, known as temperature retraction (TR10), involves stretching the rubber, applying cold temperatures, and then observing the temperature required for the rubber to return to 10% of its original length as it warms up.

Brittleness tests determine the temperature at which the rubber will break when force is applied in a cold state. However, these tests can sometimes be misleading for sealing applications. A strong or high-modulus rubber may withstand the applied force even at lower temperatures. Nevertheless, if it is beyond the glass transition temperature, the rubber may lose its sealing force and start to leak.

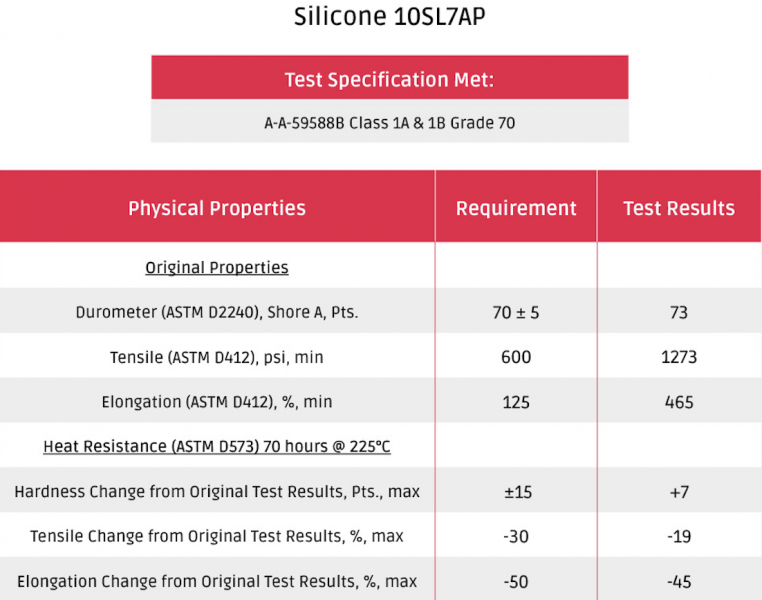

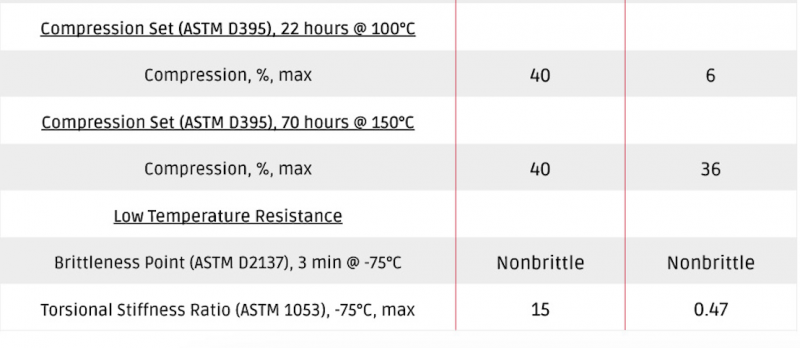

Silicone 10SL7AP

Silicone is an excellent polymer for low-temperature applications. Standard silicone can be used down to -65°C, while fluorosilicone, which offers better resistance to fuel and oil, is suitable for use at temperatures as low as -60°C. Fluorosilicone is frequently used in aerospace applications due to its outstanding low-temperature performance.

Our compound, 10SL7AP, is a phenyl-based silicone. It has been tested to meet A-A-59588 Class 1A and 1B specifications. The brittleness temperature for this specification is -75°C; however, the compound can be effectively used beyond that limit. Additionally, this compound has been tested for outgassing according to ASTM E595 standards. It passes the typical National Aeronautics and Space Administration (NASA) limits for total mass loss (TML) of less than 1% (with a result of 0.29%), but it marginally exceeds the limit for collected volatile condensable materials (CVCM), with a result of 0.11%.

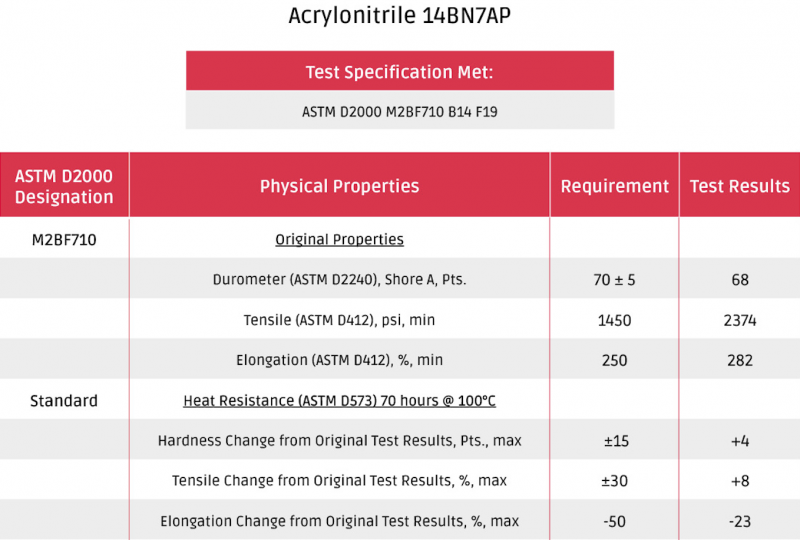

Acrylonitrile 14BN7AP

Nitrile (NBR) rubber is widely used in automotive applications due to its excellent oil resistance and reliable performance across standard temperature ranges. The full name of NBR polymer is acrylonitrile-butadiene, and these two components contribute significantly to its overall performance.

In NBR, a higher acrylonitrile (ACN) content results in lower swelling when exposed to fuels and oils. Conversely, a higher butadiene content enhances low-temperature performance. Low swell compounds typically contain 36% to 40% ACN, while standard compounds range from 28% to 33% ACN. Low-temperature compounds have less than 25% ACN.

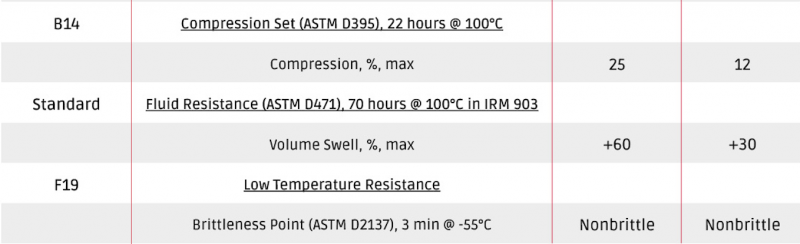

Our specific compound, 14BN7AP, contains 18% ACN. This compound has successfully passed a brittleness test at temperatures as low as -55°C. Additionally, it is listed with Underwriters Laboratories, Inc. (UL) under JMLU2 for use with liquified petroleum (LP) gas and fuel oils, with an operational temperature range from 60°C to -60°C.

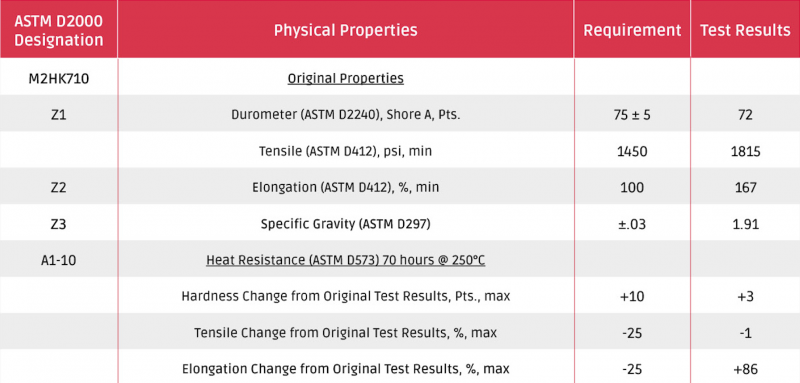

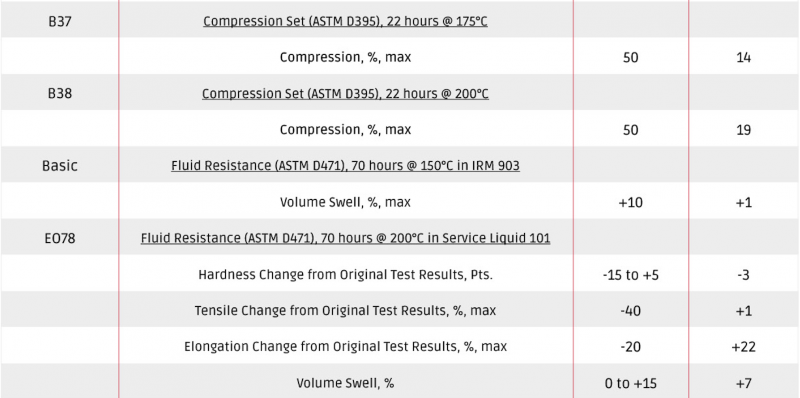

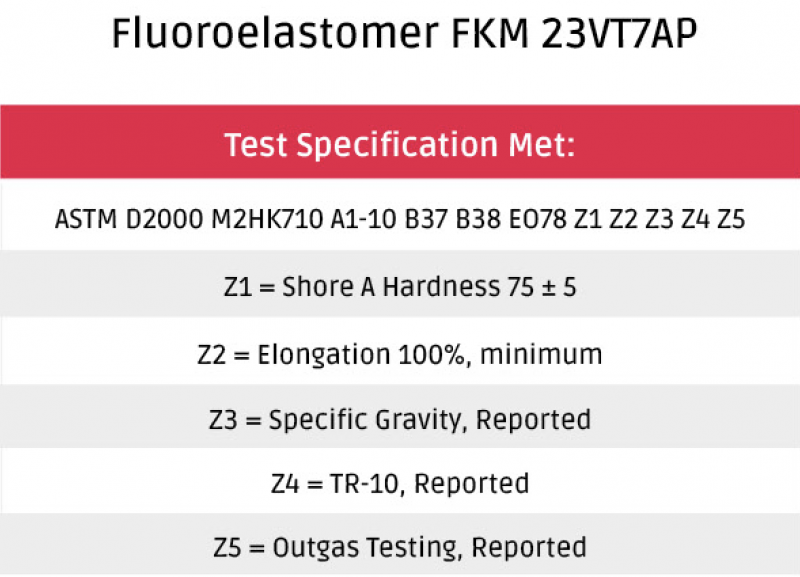

Fluoroelastomer FKM 23VT7AP

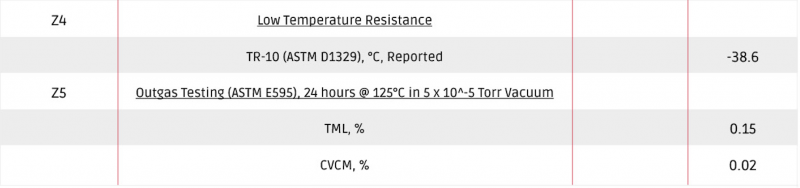

FKM, commonly known as Viton™, is not typically recognized for its low-temperature performance because not all FKM materials are the same. Standard FKM polymers are usually rated for temperatures down to -25°C. However, with modifications to the polymer, low-temperature FKM variants can now perform down to -40°C for static applications. Recent developments have introduced new polymers that can be used in some applications down to -60°C. Our compound, 23VT7AP, utilizes one of these advanced polymers. With a TR10 rating close to -40°C, this compound excels in cold-temperature performance. Additionally, it has been tested to ASTM E595 and meets the standard limits set by NASA.

However, it’s important to note that while FKM can perform well at low temperatures, this often comes at a higher cost. Generally, the lower the temperature rating, the more expensive the compound becomes, with extreme low-temperature variants costing approximately ten times more than standard options.

Choosing the right compound is essential, but having a good design is also critical. It is important to ensure that the sealing groove is designed correctly, taking tolerance effects into account. While a low amount of compression may work at standard temperatures, higher failure rates can occur at lower temperatures. Therefore, making the seal more robust, especially at the tolerance limit, is extremely important.

For dynamic applications, the Tg is critical. In static applications, performance can still occur below Tg, but as the rubber hardens in dynamic situations, normal function may cease to meet design criteria. Cold temperature compression set is rarely reported, yet it is significant for long-term exposure beyond Tg values of compounds. Higher compression sets can be observed at lower temperatures compared to high-temperature values.

From a company that sits in a Lake Effect snow belt, let us help with your low temperature sealing application.