As a supplier in the rubber industry, it is important to implement and be aware of storage guidelines to ensure the best possible quality of an elastomer for the user. Some common standards that provide guidelines for storage include SAE AS5316 and ISO 2230. SAE AS5316, developed by SAE International, is an aerospace standard that is preferred in the North American area. This standard focuses on data recording, packaging, and storage of elastomeric seals and seal assemblies. Similarly, ISO 2230 is an international standard that focuses on the guidelines for inspection, packaging, and storage of rubber products. Overall, ISO 2230 is a broader standard for all rubber products, while AS5316 is more specific to aerospace seals.

Recommended Storage Guidelines per Standard

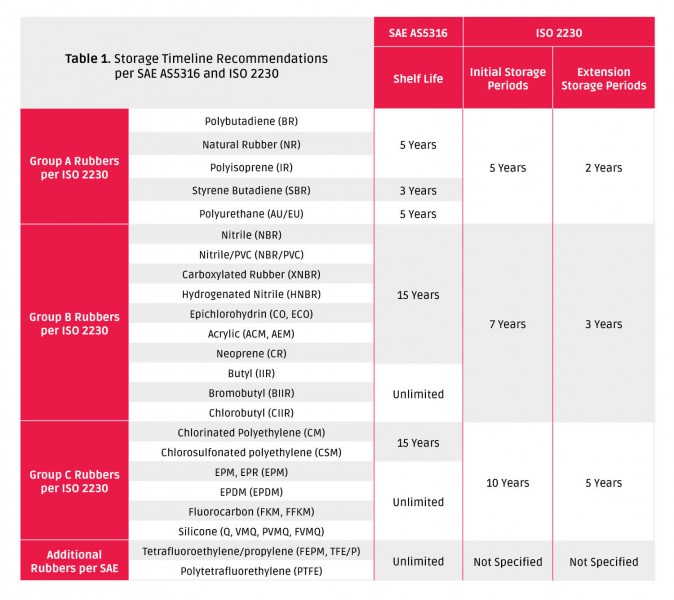

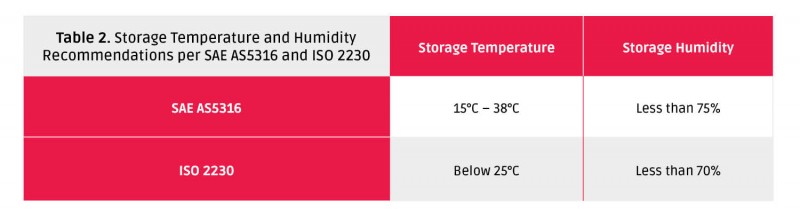

As shown below, Table 1 compares the SAE AS5316 recommended shelf life to the ISO 2230 recommended initial and extension storage periods. Per ISO 2230, the initial storage period is defined as the maximum period a rubber product can be stored before a product needs to be inspected or retested. This period begins at the time of manufacture and is applicable if products are appropriately packaged and held at the recommended conditions. Some of these conditions, including storage temperature and humidity, can be found below in Table 2. Similarly, the extension storage period is defined as the period after the initial storage period during which a rubber product can be stored before further inspection and re-testing. The recommended packaging and storage conditions are the same for this period as for the initial storage period.

Major Differences and Similarities Between SAE AS5316 and ISO 2230

As seen in the tables, the ISO 2230 standard can be considered more stringent than AS5316 with more defined storage periods, as well as stricter storage temperature and humidity recommendations. Another difference between these standards is in their packaging guidelines. ISO 2230 recommends heat-sealable opaque materials like PE-coated Kraft paper, PE laminate, or aluminum foil/paper, while AS5316 recommends individual or bulk packaging with guidelines to maintain traceability among batches. SAE AS5316 also emphasizes first-in, first-out (FIFO) rotation of stock.

A similarity among these standards is that they both recommend a controlled environment for storage. This includes aspects such as UV light, radiation, and removal of incompatible chemicals. Both SAE AS5316 and ISO 2230 focus on maintaining the longevity and quality of rubber products and offer guidelines specific to storage timelines and packaging for proper storage conditions. Conclusively, SAE AS5316 is targeted to the needs of the aerospace industry with the focus on practical storage aspects like temperature, humidity, and stock rotation. Alternatively, ISO 2230 is a broader standard for general rubber products and focuses on detailed guidelines for inspection, packaging, and storage periods.