The world is more connected than ever. Manufacturers face serious challenges: an evolving economy, an aging workforce, the arrival of big data, complex compliance requirements and the constant pressure to stay ahead of the competition. Cloud-based solutions can help manufacturing organizations succeed in the face of these economic, social and performance-based forces.

What is the cloud?

The cloud simply refers to software and services that run on the internet instead of the computer. Apple iCloud, Netflix, Dropbox and Google Drive are all popular consumer examples of the cloud — and businesses are increasingly ditching their internal servers and software in favor of cloud-based ones.

Cloud-based strategies allow manufacturers the opportunity to bring their own knowledge into every sales situation. The cloud rapidly increases speed and volume between suppliers and distributors which significantly improves workflow.

“The best manufacturers I’ve visited this year all share a common attribute: they are obsessed with making themselves as easy as possible to work with from a supply chain, distribution and services standpoint,” notes Louis Columbus, Forbes Tech contributor. “Many are evaluating cloud-based manufacturing applications including Enterprise Resource Planning (ERP) and have adopted cloud-based applications across their companies.”

5 ways the cloud is improving the manufacturing process

1. Improved collaboration. Cloud-based software can be used at any time on almost any device with an internet connection — leading to greater collaboration for any manufacturing business. In a Microsoft survey, 66 percent of small and medium-sized businesses said they need to be able to allow employees to work anywhere at any time.

Some cloud-based services even make it possible to include customers or vendors in meetings. This improved sharing of information can enable organizations to react more quickly to business opportunities.

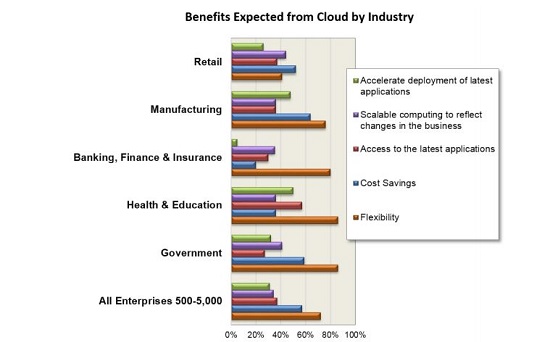

2. Cost savings. According to a Cisco survey, manufacturing organizations place a much higher priority on cost savings than organizations in other vertical markets. Given the need to drive down costs to improve profits, it’s no surprise that more than half of the respondents in manufacturing indicated that cost savings are a major benefit of the cloud.

When determining if the cloud system is more cost-effective than on-premise software, manufacturers also tend to make the mistake of comparing month-to-month recurring costs with the upfront capital expenditure on purchasing licenses.

“This is actually an inaccurate comparison, since you’re only considering the costs of licensing and not the numerous additional expenses associated with on-premise solutions that you’ll end up avoiding altogether,” notes Doug Fair of Manufacturing Business Technology. “This includes purchasing, installing, maintaining serves and other infrastructures. So over time, a cloud solution is actually much more cost-effective than an on-premise solution — and who doesn’t want to save money?”

3. Secure data. Manufacturing organizations may be concerned with the security of important company data. In the 2014 Cloud Security Report, however, Alert Logic revealed that 56 percent of on-premise users suffered malware attacks while only 11 percent of on-demand users did.

It’s even possible for companies that abide by legal requirements dictating that they must control data within their own four walls to deploy a private cloud solution. With the cloud, an organization would have to invest in its own servers, database infrastructure and IT staff — but those additional costs would allow the company to reap the benefits of the system.

4. Fast reporting (and significant ROI). The cloud allows manufacturers to set up precise, fast reporting and see significant return on investment.

Epec Engineered Technologies, a leader in designing and manufacturing custom build-to-print electronic products, recently won the 2015 Manufacturing Leadership Award for its cloud-based ERP technology. It has helped the company with lean, agile manufacturing and supply chain execution, while improving business efficiency and scalability for global growth.

The company saved on the cost of four full-time personnel previously required at partner facilities in China while netting return on investment (ROI) of more than $500,000 from cloud technology since 2007.

Reporting that took weeks is now accomplished in a matter of minutes, while sales personnel have doubled daily sales quote volume without additional staff. Building on its success, Epec added 4,000 square feet of new manufacturing space to its Massachusetts headquarters in 2014, bringing the facility to 24,000 square feet.

“The Manufacturing Leadership Awards Judges were very impressed with how Epec Engineered Technologies aggressively adopted new technologies to transform operations for better efficiency and innovation,” said Jeff Moad, research director and executive editor at Frost & Sullivan’s Manufacturing Leadership Council. “With considerable help from NetSuite, Epec has been able to focus on customer-centric execution that’s driving growth.”

5. Enhanced globalization. Many of today’s manufacturers fall short of their global aspirations due to IT systems that make it difficult to extend infrastructure into other regions of the world. Cloud-based infrastructures allow manufacturers to overcome these restrictions and allow them to seek new business opportunities in any region of the world. Cloud-based services can readily facilitate communication tools for effective teaming across a global supply chain.

ARC President Andy Chatha recently highlighted the importance of building cloud-based, company-wide networks to bridge the gap between the various departments within a manufacturing operation.

“You truly need to bring your entire organization together,” Chatha notes. “U.S. manufacturers need to become more innovation-centric to increase their global competitiveness, and technology is our ace in the hole.”

Benefit from the cloud

Manufacturers feel constant pressure to increase accuracy, improve processes and capitalize on their intelligence to make every interaction count. The cloud is helping them reach these goals.

By using cloud-based systems to streamline key areas of their business, manufacturers can free up more time to invest in developing and selling new products.

How has the cloud impacted your manufacturing process? How have you benefited from the system? We’d love to chat. Connect with us on Twitter @AppleRubber.