Many designers apply material certifications to rubber part prints. The goal of this is to assure a specific level of quality from the material used to make the part. A good design is successful when you get the same quality in the material from part to part. Of course, choosing the wrong specification could also cause problems with part performance and cost.

Let’s talk about FKM specifications.

A standard for a long time for FKM or Fluorocarbon (commonly referred to as Viton™) was MIL-R-83248 “Rubber, Fluorocarbon Elastomer, High Temperature, Fluid and Compression Set Resistance”. This was later replaced by AMS-R-83248. As of September 2005, the Aerospace Materials Division “Cancelled” this and has been superseded by AMS 3216, AMS 3218, AMS 7259 and AMS 7276*. These standards are for FKM compounds 75 and 90 durometer shore A. The formulations can be either Black or Brown in color. The standards give physical properties, incoming inspection, dimensional tolerancing and packaging requirements.

Another important part of these standards is whether or not the rubber manufacturer is required to list the compound on the Qualified Products List or QPL. This requires the material to be specially tested and approved by a registering body. This also requires certain qualification of the manufacturing process and internal testing laboratory. Since there is a very big expense to have these listing and there are relatively few rubber manufactures that have this listing, it can greatly increase the price of the product to have this specification assigned to the parts. Typically only high level aerospace or military applications require this specification. Currently AMS 3216 Rev G (75 Durometer) and AMS 3218 Rev C (90 Durometer) don’t require the compounds to have QPL listing. This allows the designer to having the same material requirements but not the extra cost of having a QPL listed compound.

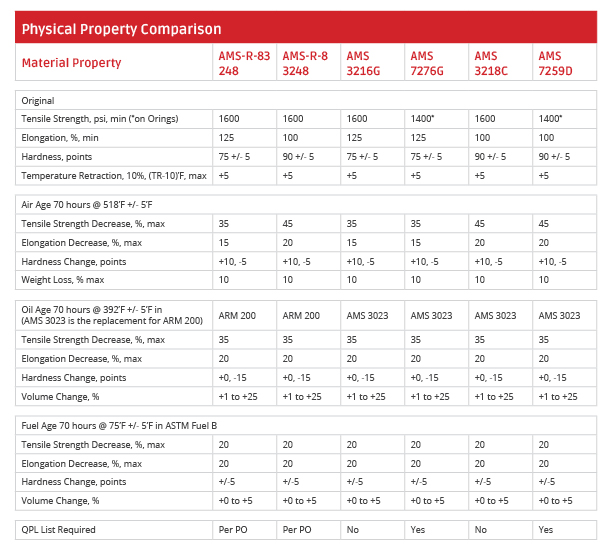

Below is a comparison of the specifications stated above to show similar physical properties between specifications. Actual documents should be purchased to see full physical property testing.

Something additional to consider with picking the correct FKM specification is material performance. All the above standards are for dipolymer compounds. This polymer can give low compression set at high temperature but is only marketed to perform to -20’F. Other polymers are available to give higher chemical resistance and improved low temperature performance, such as Viton ETP.

Another way to help reduce cost is to use an ASTM D2000 call out instead of referencing an Aerospace specification that may add to part cost. Using this type of call out gives the flexibility to utilize other types of FKM polymers that give different performance advantages.

Questions on this post or specific material specifications? Feel free to contact our engineering team. We’ll work with you to make sure you have the correct material for your O-Ring or custom-molded project.