Apple Rubber: O-Rings in Standard and Non-Standard Sizes

An o-ring is a toroidal elastomeric sealing device designed to prevent the passage of fluids or gasses between two mating surfaces under static or dynamic conditions. Its cross-sectional circular geometry creates a compression seal when installed in a properly dimensioned gland or groove. An elastomeric material's inherent resilience allows it to conform to surface irregularities, maintaining seal integrity across a wide range of pressures, temperatures, and chemical environments.

O-Rings function based on the principle of zero-gap sealing, where the compressive force exerted by the mating surfaces deforms the o-ring, creating a barrier against leakage. This elegant yet highly effective sealing solution finds widespread application across numerous industries, from aerospace and automotive to medical sectors.

Our Advanced O-Ring Inventory

Apple Rubber employs a state-of-the-art approach to o-ring procurement and production, maintaining one of the industry's most extensive and diverse inventories. Our vertically integrated manufacturing process, featuring in-house tooling and production capabilities, enables rapid prototyping and accelerated delivery timelines.

Specifications of Apple Rubber’s O-Ring Inventory

- Compliant with AS568 and ISO 3601 standardized dimensional parameters

- Shore A durometer range: 10-90, accommodating varied compression set requirements

- Extensive array of 8,000+ non-standard sizes

- Proprietary MicrOrings® technology: Capable of producing inner diameters < 0.036" (1 mm)

- Domestic manufacturing options available to meet specific regulatory requirements

- Right-on-time inventory management enabling prompt fulfillment of high and low-volume orders

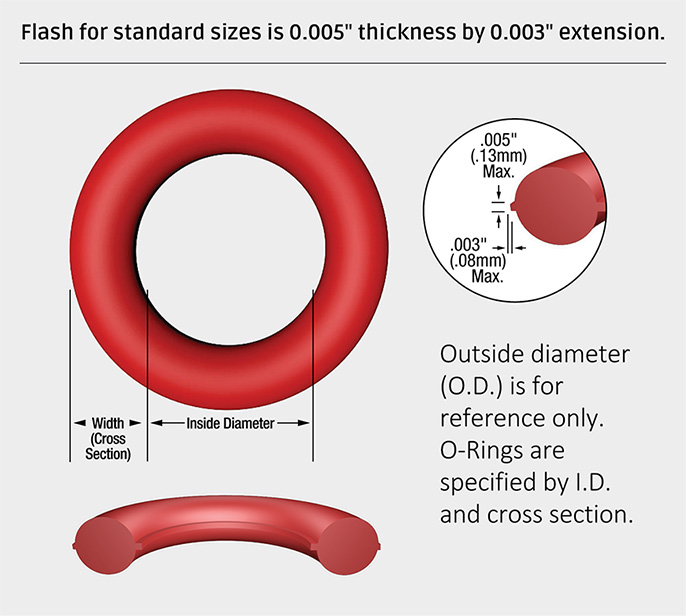

Standardized O-Ring Sizing Protocols

We adhere to aerospace standard AS568 and ISO 3601 for metric configurations, ensuring precise dimensional tolerances. These standardized sizes offer optimal availability and are recommended for new engineering designs. Our advanced CAD tools facilitate groove design for both static and dynamic sealing applications.

- AS568 Standard O-Ring Dimensional Chart

- ISO 3601 Metric O-Ring Specifications

- Comprehensive O-Ring Inventory Database

Streamlined Procurement Process

Start your order by submitting a detailed RFQ through our online portal for prompt quotation by our technical sales team. Our extensive inventory management system likely encompasses your required o-ring dimensions and material specifications. We utilize advanced logistics to ensure expedited shipment with minimized lead times.

Material Science and Elastomer Engineering

Our product line includes six primary elastomeric compounds, each available in a spectrum of durometer (Shore A) hardnesses to meet diverse operational parameters. While these represent our core offerings, our materials science team can formulate custom elastomeric compounds to meet your specific performance criteria.

|

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Common Name | ASTM D1418 | ASTM D2000 Class | Standard Temperature Range (°F) | Special Temperature Range (°F) | Petroleum Fluids | Ozone | Resistance Weather (UV) | Vacuum | Compression Set | Resilience | Special Applications |

| Nitrile | Buna-N | NBR | BG | -40 to +257 | -76 to +275 | 1 | 4 | 4 | 2 | 1 | 2 | Hydrogenated Nitrile (HNBR) improves ozone and weather resistance |

| Fluorocarbon | Viton™ | FKM | HK | -13 to +446 | -31 to +446 | 1 | 1 | 1 | 1 | 1 | 1 | Custom compounds improve chemical and low-temperature resistance. |

| Ethylene-Propylene | EPDM | EP | BA | -40 to +275 | 4 | 4 | 4 | 2 | 2 | 2 | Good for water, steam, solvents and acids | |

| Silicone | Silicone | VMQ | GE | -85 to +400 | -148 to +400 | 3 | 1 | 1 | 4 | 1 | 2 | Popular for food and medical applications |

| Fluorosilicone | Fluorosilicone | FVMQ | FK | -75 to +400 | 1 | 1 | 1 | 3 | 1 | 2 | Low outgassing, used in military and aerospace applications | |

| Chloroprene | Neoprene® | CR | BC | -40 to +250 | General Purpose | 2 | 2 | 2 | 2 | 2 | 2 | Used in refrigerations industry for resistance to ammonia and Freon® |

Technical Support and Material Selection

Use our Interactive Material Selection Guide to determine the optimal elastomer compounds for your application. For in-depth technical consultation on o-ring dimensioning or material selection, please contact our engineering support team.