There are countless qualities to rubber materials that can add time and complexity to the sealing process. Tolerances, compression set and environmental factors are just some of those components. Also on that list is the hardness of the material: Durometer.

Durometer is typically used as a measure of hardness in polymers, elastomers and rubbers — and can also be a difficult property to measure. It’s geometry-dependent, which requires thorough testing.

Durometer Testing

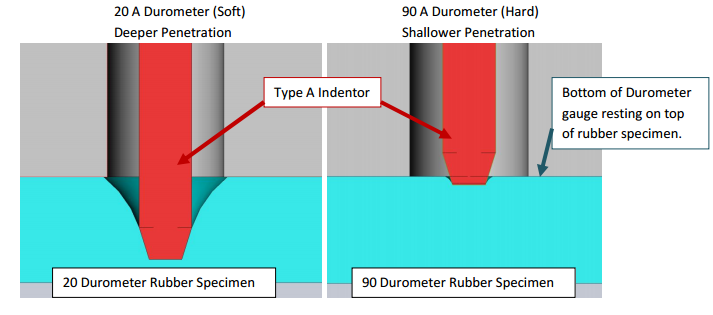

The hardness of elastomeric materials comes down to one component: the depth that a spring-loaded indenter penetrates through the specimen. The softer the specimen, the farther the indenter will penetrate.

Several standard test methods exist for the measurement of rubber hardness. ASTM D-2240 and ISO-868 are the two most common specifications that we see. Both specifications are used for materials ranging from 20 to 90 durometer. Gauges for these standards can be analog or digital.

To give you an idea of how a specific durometer hardness translates into feel, here are some examples. Rubber bands are approximately 40 A Durometer, while standard O-Ring seals are 70 A durometer:

Official specifications list the different durometer scales as types. Specifically, we investigate type A and type M durometer scales — as these are commonly used to measure the hardness of elastomer materials used for seals. Another common way to describe the hardness scales is Shore — such as Shore A or Shore M.

Let’s dig in to how we tell the difference between the two types.

Differentiating Durometer Shores

The term Shore comes from Albert Shore, founder of the Shore Instrument Company and the man who originally defined the scales. Any specification may be referred to as either a Shore or Type — for example, “Shore A 70 durometer” or “Type A 70 durometer.”

Type (Shore) A Durometer

Shore A durometer is appropriate for measuring the hardness of specimens that are flat, parallel, and of a certain minimum thickness. ASTM and ISO each specify different minimum thicknesses:

ASTM D-2240 Type A Minimum Thickness: 0.24 inches

ISO -868 Minimum Thickness: 4mm (0.157 inches)

Dumbell specimens are typically plied to create a total thickness of at least 0.24 inches. The shore A indentor will deflect 0.001 inch for every durometer point.

Type (Shore) M Durometer

Type M durometer is described as a micro hardness gauge. It is appropriate for measuring the hardness of specimens that cannot be accurately measured using the Shore A device like orings. Type M durometer is intended for use on specimens having a minimum thickness of 0.050 inches, although it can be used on thinner specimens if there is data supporting the accuracy of the measurement.

ASTM D-2240 Type M Minimum Thickness: 0.050 inches

The Shore M indentor will deflect 0.0005 inches for every durometer point.

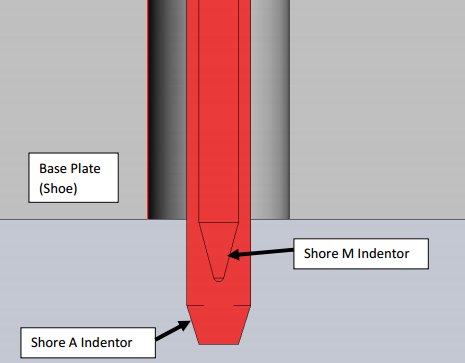

At zero, the Shore A and Shore M indentors overlaid resemble below:

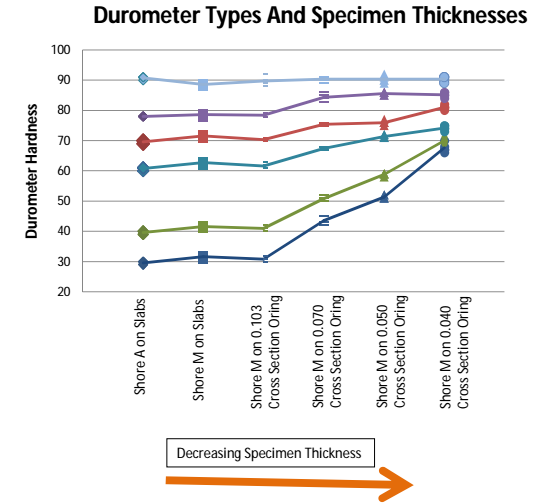

It is important to note is that Type A and Type M durometer readings are not always the same, due to the geometric and thickness component to the hardness reading. As specimen thickness decreases, the gauge is reading more and more of the base material underneath the specimen. This base material is steel, so readings on thin specimens generally exhibit artificially higher (harder) results.

This effect is mitigated when harder specimens are measured, as the harder specimens keep the indentor further away from the steel base.

The data shows that specimen thickness does play a role in elastomer hardness measurement. A minimum specimen thickness of approximately 0.100 inches is required to achieve consistent results when measuring common rubber materials. Here is the breakdown: