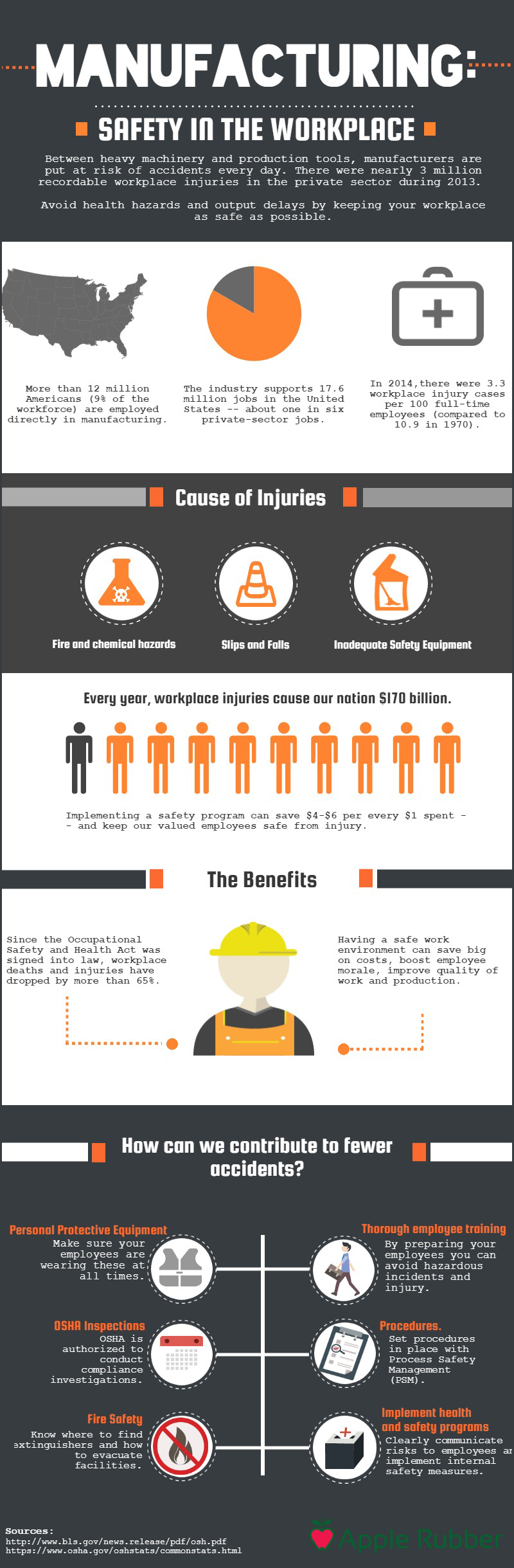

More than 12 million Americans are employed in manufacturing, according to the Bureau of Labor Statistics — that’s 10 percent of the U.S. workforce. In an industry of this magnitude, ensuring employee safety is both a necessity and a challenge.

Avoiding Injury in the Workplace

In 1970, manufacturing saw as many as 14,000 worker deaths caused by injury. In response to these calamities, the Occupational Safety and Health Act (OSHA) was signed into law, helping occupational injuries to drop by more than 65 percent. By 2014, there were only 3.3 workplace injury cases per 100 full-time employees.

Workplace safety in a manufacturing environment has three components:

- The company must eliminate hazards.

- The company must establish policies that protect workers.

- The company must follow the rules.

Basic safety rules are designed to reduce any possible risks, but accidents happen — and manufacturers want to be able to eliminate these accidents as quickly and efficiently as possible.

Below, take a look at common causes of injury, what it means for manufacturers, and the crucial importance of understanding health and safety hazards:

“We are extremely committed to the safety of our employees,” says John Tranquilli, materials manager at Apple Rubber. “An internal safety committee meets once per month to review procedures, address employee input and implement new rules in the case of accidents.”

What are some of the safety challenges facing you and your organization? We’d love to hear your thoughts. Connect with us in the Comments section or find us on Twitter @AppleRubber.