As 3D printing shapes the direction of healthcare, medicine, aviation, sports, biotechnology and other industries, we can now see how this new technology is changing the final frontier.

Near the end of June — just a few weeks from now — the European Space Agency is set to send its first 3D printer to the International Space Station (ISS) to experiment with zero-gravity manufacturing on long space voyages.

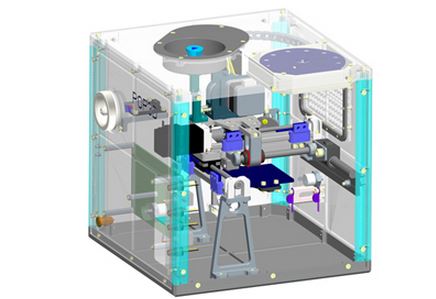

Meet the POP3D

Known as the Portable On-Board 3D Printer (POP3D), the printer measures only 10 square inches (“a cube with 25 cm sides,” according to the ESA) and requires a small amount of power and limited crew involvement to operate. Although the printer uses heat-based processes to create components and tools, it will not affect the station’s fragile environment – using only safe, biodegradable plastics in the printing process.

“The POP3D Portable On-Board Printer is a small 3D printer that requires very limited power and crew involvement to operate,” said Luca Enrietti of Altran, prime contractor for the compact printer, in a European Space Agency (ESA) statement.

Designed and built in Italy, POP3D will be put to the test as part of ESA astronaut Samantha Cristoforetti’s Futura mission. The printer should take about a half hour to produce a single plastic part, which will eventually be returned to Earth for detailed testing.

ESA’s goal is to increase the technological maturity of the additive manufacturing process for extrusion of thermoplastic polymers in microgravity conditions and in manned space environment.

U.S. 3D Printing: Leading the way

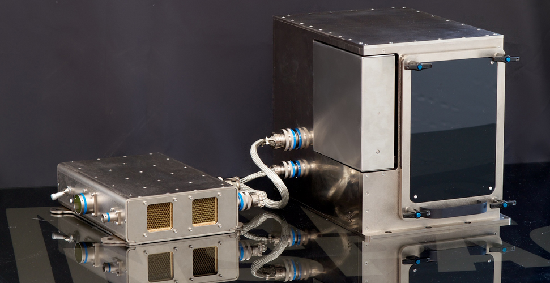

The POP3D may be the ESA’s first zero-gravity printer, but it is not the first to make it to space. In September of 2014, the SpaceX delivered a zero-gravity printer designed and built by California-based startup Made in Space to the International Space Station.

“This is the first object truly manufactured off of planet Earth,” Made In Space CEO Aaron Kemmer told Space.com about the first successful zero-gravity print. “It’s a huge milestone, not only for Made In Space and NASA, but for humanity as a whole.”

A massive benefit is the ability to print broken parts on-site, as opposed to using rockets to bring pre-manufactured items for space missions. Later in 2014, NASA emailed CAD drawings for a socket wrench to astronauts aboard the ISS, who then printed the tool using its 3D printer.

3D Printing in Space: Part of a grander vision

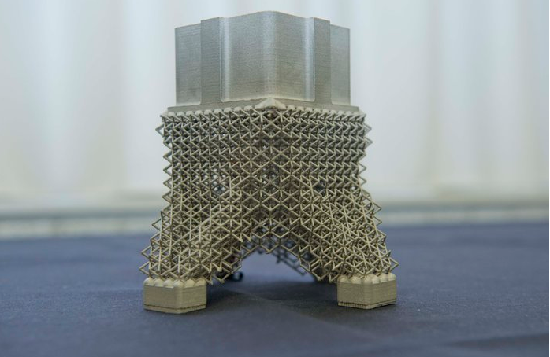

Both the SpaceX and POP3D mark groundbreaking steps towards manufacturing goods outside of Earth’s gravity. Successful 3D printing with plastic is one thing, but the ultimate goal is to perform additive manufacturing with a whole range of materials – like aluminum and other key aerospace applications.

3D printing space capabilities will mean the following:

- As long as 3D printing continues to work in zero gravity, it will be faster, more efficient and much easier to make the parts that members need on the ISS (rather than defeating Earth’s gravity by burning millions of dollars of rocket fuel).

- Using 3D printing technology reduces volumes of cargo on board, since functional parts could be produced directly according to the actual needs.

- The ISS would be able to avoid designing parts on the basis of high mechanical stresses they are subject to during the launch phase.

Ultimately, as NASA and other space agencies move towards sending humans to the Moon, asteroids, and Mars, advanced 3D printers are likely to play a key role in humanity’s colonization of the Solar System — and in enabling the future of space exploration.

What are some of your latest innovations in 3D printing? We’d love to hear your thoughts on Twitter @AppleRubber.