A newer polymer has been gaining more acceptance in the sealing industry to replace expensive materials like FFKM or fluoropolymer while providing greater chemical compatibility to standard FKM grades — Viton ETP®.

See our Lab Report for Viton ETP®.

Two recognized FFKM grades are Dupont’s Kalrez™ and Greene Tweed’s Chemraz™. A new polymer was designed to give similar chemical resistance of the FFKM polymers, but does not have the same high temperature (+300’C) performance.

Dupont’s Viton ETP® fluoroelastomer is a peroxide-cured FKM designed for extreme applications. ETP® gives resistance to fuel, solvents, acids, bases and amines, while also providing a good working temperature range of -25’C to 200’C. Viton ETP® is just a polymer base, so compounding of the rubber still applies. Various filler systems can be used to change hardness and color.

Viton ETP® is on a magnitude of 10 times less expensive than a FFKM compound.

Quick facts on Viton ETP®:

- Excellent resistance to acid, hydrocarbon and low molecular weight esters, ketones and aldehydes

- Inherent resistance to base attack and volume changes in highly caustic solutions, amines and hot water

- Low temperature flexibility (Tg – 10’C)

- Apple Rubber currently has a 75 and 90 Shore A durometer. Additional compounds can be developed to meet application needs.

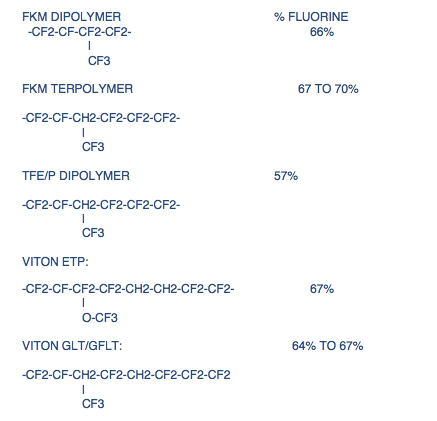

Viton ETP® is a tetra polymer of ethylene, tetrafluoroethylene (TFE) and perfluoromethylvinylether (PMVE). This chain structure is designed to give excellent resistance to base and polar fluids, while retaining good low-temperature flexibility and general fluid resistance comparable to FFKM materials.

Standard Viton® (Type A, B or GF) polymer structures are susceptible to attack by base and amines fluids. Changes to the structure in ETP® offer non-polar groups that resist attack by base and polar fluids.

Aflas™ also provides base-resistance. The difference? ETP® contains 67 percent fluorine, while Aflas™ (TFE/P) contains only 57 percent. The higher fluorine content gives ETP® the typical high-fluorine performance expected in aromatic and aliphatic hydrocarbons. Aflas™ trades base resistance for lower hydrocarbon resistance.

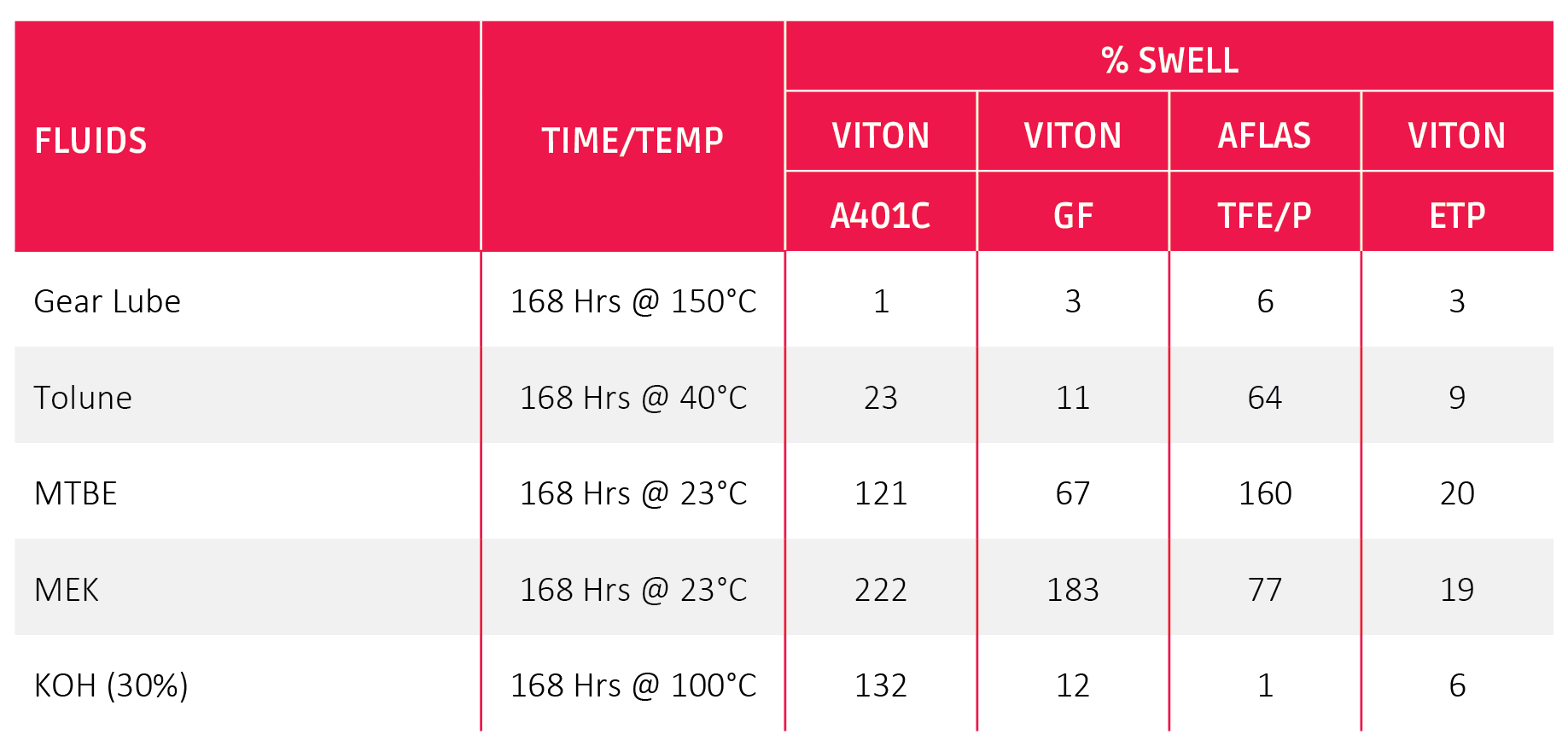

In the spreadsheet below, we can see comparison test data between Viton A ®, Viton GF®, TFE/P, and Viton ETP®. Another very good industry for this polymer is in the oil field environment. Below is a comparison of ETP® to Viton GF®.

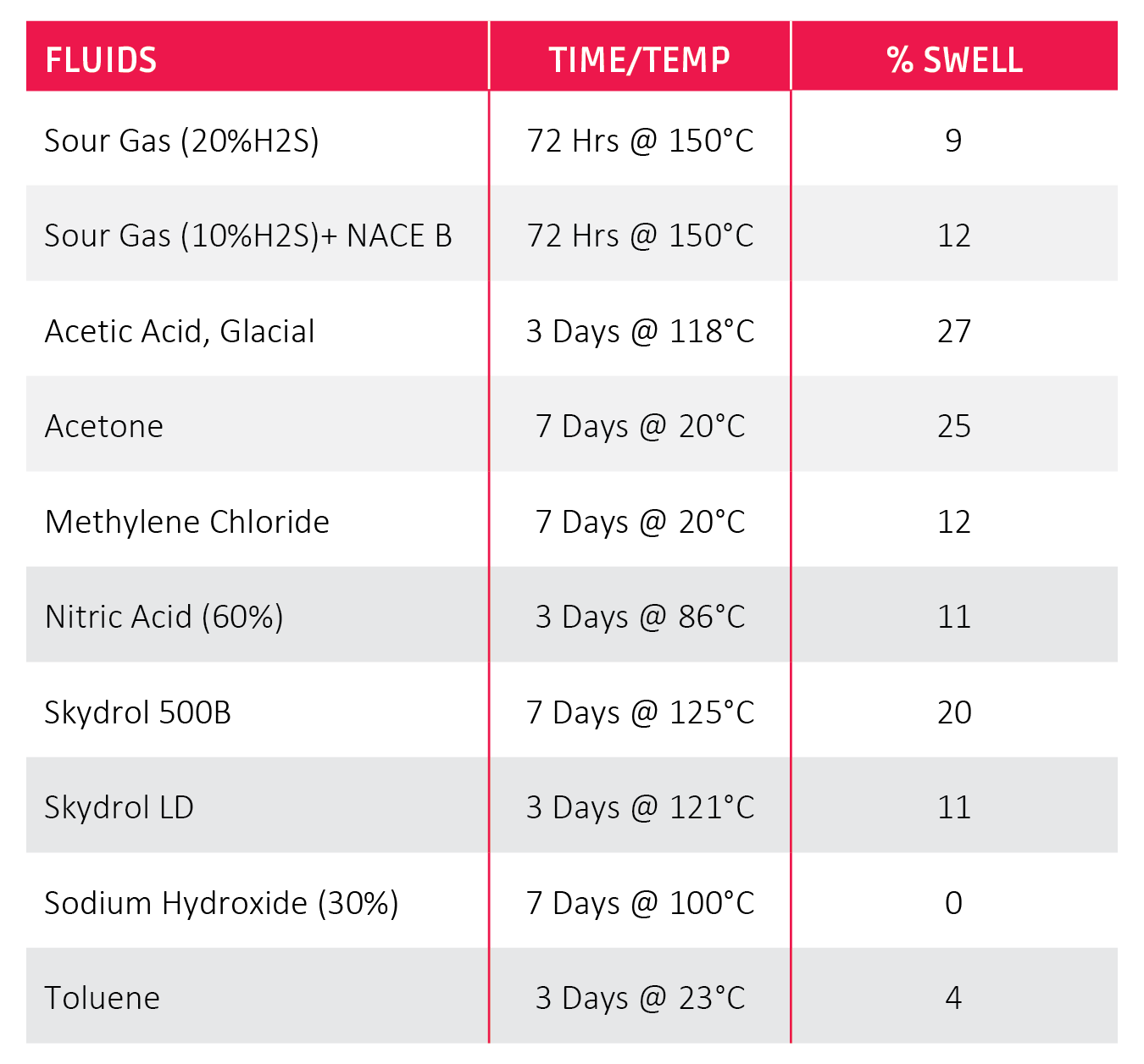

Below are some additional fluid resistance. (% Volume Swell)

1- Ronald Stevens, “Viton® ETP – A New, Unique Fluoroelastomer With Expanded Fluids Resistance.” Paper prepared for Energy Rubber Group Meeting, January 1998.

2 – Chemours Chemical Resistance Guide.