As we discussed in Part I, engineers conduct certain tests to gain a complete picture of the low-temperature properties of a specific rubber compound. Applications in major industries like automotive and railroad demand peak seal performance in cold environments. Since there is no universal test that provides all of the necessary information, engineers must perform the appropriate tests for a given situation.

Let’s reflect on the three standard low-temperature tests that help measure physical characteristics and material performance:

- Brittleness (ASTM D2137). This test measures the ability of a material to withstand breaking when bent at a given temperature for a specific period of time.

- Temperature Retraction (ASTM D1329). This measures the temperature at which frozen rubber returns to an elastic state.

- Torsional Stiffness Ratio (ASTM D1053). This measures the ratio from when a material is twisted, first at room temperature and then at a given low temperature.

Some of the other tests used are the ASTM D7426 glass transition test and a slight variation of the ASTM D2240 durometer test. While we focused on ASTM D2137 in Part I, today we will focus on ASTM D7426.

What is ASTM D7426?

The ASTM D7426 glass transition test is fairly common in the rubber industry. The test uses a differential scanning calorimeter to measure the difference in heat flow between a material and a reference to determine the Tg or glass transition point, which is the temperature at which a material enters a glass-like state.

Differential scanning calorimetry provides a rapid test method for determining changes in specific heat capacity in a homogeneous material or domain. The glass transition test is manifested as a step change in specific heat capacity. For amorphous and semi-crystalline materials, the determination of the glass transition temperature may lead to important information about their thermal history, processing conditions, stability of phases and progress of chemical reactions.

For determining Tg of an elastomeric compound, we use a TA Instruments DSC 2010 with a quench-cooling accessory.

The process:

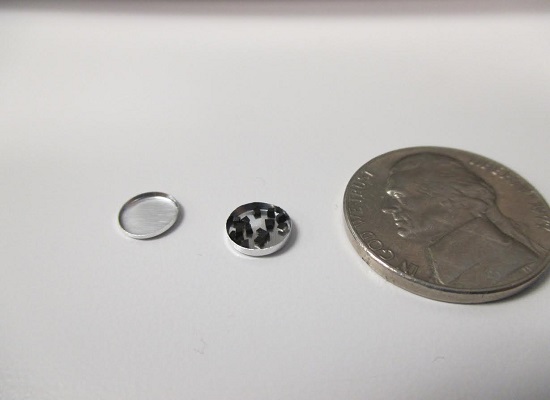

To start, we cut or punch a small piece of cured material out of a test slab. The specimen is trimmed down to about 5 milligrams. Most other materials may use more, but this is sufficient for many elastomers.

Next, we seal the specimen in a sample container. Ideally, there should be no gap in the exterior of the sample container to allow air movement — this can affect heat flow of the sample.

Using liquid nitrogen, the sample is cooled to -100°C and the temperature equilibrates. We then heat the sample at a rate of 10°C until all desired transitions are complete.

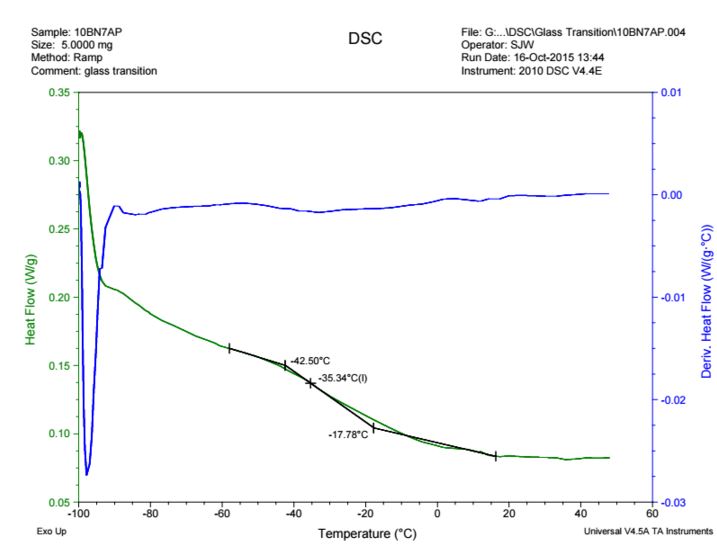

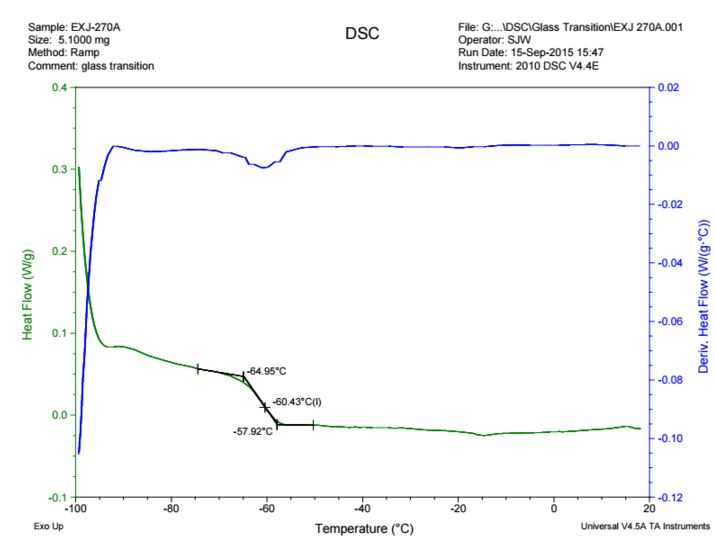

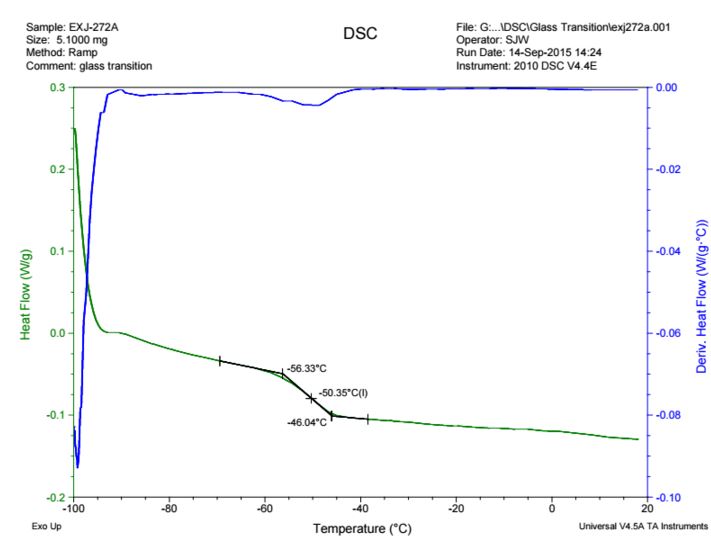

It’s important to note that with most materials, this would need to be done twice in order to establish a heat history — but since elastomers have a Tg of less than room temperature, there is no need to establish that heat history. The data is shown below for the three materials from Part I EXJ-270A, EXJ-272A, and 10BN7AP:

Glass transition test: The results

The glass transition test is great for determining when an elastomer is going start losing its elastomeric properties. However, the test is not necessarily a good indicator of sealing temperatures.

The glass transition test can provide a reference for when a material will stiffen in the groove, but when compared to the brittleness test, one can see in our results that the strongest material (or 10BN7AP) starts changing through its glass transition point at much warmer temperatures than the other materials. This indicates that in a dynamic application, stiffness could increase and cause too much force for that motion as the temperature drops.

Tip: When looking for a minimum sealing temperature, everything must be considered: the extrusion gap, pressure, type of fluid, if the application is static or dynamic and the brittleness point.

Combined with the brittleness test, the glass transition temperature can provide a good starting point to find a seal’s minimum temperature.

Putting low-temperature testing to use

Low-temperature performance is a very important characteristic of elastomeric compounds. Reducing the temperature of the environment surrounding the rubber article will have a negative impact on the rubber properties, which is why thorough testing is always essential to seal success.

Which low-temperature tests do you find to be most effective for rubber seals and components? What success have you had with ASTM D7426? We’d love to hear your thoughts. Connect with us on Twitter @AppleRubber or contact one of of our expert engineers.